TR Tie Rod Hydraulic Cylinders

Detailed Drawing

Model Code System

Tie Rod Hydraulic Cylinder

Tie rod hydraulic cylinders are robust and versatile components used in various industrial and agricultural applications. They consist of a cylinder barrel, piston, piston rod, and end caps connected by tie rods. These tie rod hydraulic cylinders are known for their durability, ease of service and repair due to the tie-rod design, and ability to withstand high pressure. Suitable for diverse applications, they come in various sizes and can be customized to meet specific requirements.

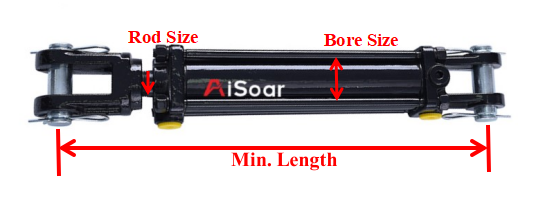

TR Hydraulic Cylinder Drawing

We can check the main sizes in below drawing

| DIMENSIONAL DATA IN INCHES(MILIMETERS) | ||||||||||||||||

| BORE | A | B | C | E | G | H | I | J | M | P | Q | R | S | T | V | W |

| 2 | 10.25 | 0.189 | 3/8NPT | 2.44 | 2.677 | 1.142 | 1.18 | 2.125 | 2 | 0.394 | 1 1/8-12UNF | 1.016 | 1.772 | 2.086 | 3.22 | 2.875 |

| (50.80) | (260.40) | (4.80) | (62.00) | (68.00) | (30.00) | (30.00) | (54.00) | (50.80) | (10.00) | (25.80) | (45.00) | (52.00) | (83.00) | (73.00) | ||

| 2.5 | 10.25 | 0.189 | 3/8NPT | 2.44 | 2.677 | 1.142 | 1.18 | 2.125 | 2 | 0.394 | 1 1/8-12UNF | 1.016 | 1.772 | 2.086 | 3.22 | 2.875 |

| (63.50) | (260.40) | (4.80) | (62.00) | (68.00) | (30.00) | (30.00) | (54.00) | (50.80) | (10.00) | (25.80) | (45.00) | (52.00) | (83.00) | (73.00) | ||

| 3 | 10.25 | 0.189 | 1/2NPT | 2.717 | 2.677 | 1.142 | 1.18 | 2.125 | 2 | 0.472 | 1 1/4-12UNF | 1.016 | 2.031 | 2.086 | 3.858 | 3.78 |

| (76.20) | (260.40) | (4.80) | (70.00) | (68.00) | (30.00) | (30.00) | (54.00) | (50.80) | (12.00) | (25.80) | (51.60) | (52.00) | (98.00) | (96.00) | ||

| 3.5 | 10.25 | 0.189 | 1/2NPT | 2.717 | 2.677 | 1.142 | 1.18 | 2.125 | 2 | 0.472 | 1 1/4-12UNF | 1.016 | 2.031 | 2.086 | 4.331 | 3.78 |

| (86.90) | (260.40) | (4.80) | (69.00) | (68.00) | (30.00) | (30.00) | (54.00) | (50.80) | (14.00) | (25.80) | (51.60) | (52.00) | (110.00) | (96.00) | ||

| 4 | 10.25 | 0.189 | 1/2NPT | 2.717 | 2.717 | 1.142 | 1.18 | 2.125 | 2 | 0.63 | 1 1/4-12UNF | 1.016 | 2.126 | 2.086 | 5.157 | 5.118 |

| (101.60) | (260.40) | (4.80) | (69.00) | (69.00) | (30.00) | (30.00) | (54.00) | (50.80) | (16.00) | (25.80) | (55.00) | (52.00) | (131.00) | (130.00) | ||

| 5 | 12.25 | 0.25 | 1/2NPT | 2.992 | 2.913 | 1.26 | 1.26 | 2.125 | 2.118 | 0.72 | 1 1/4-12UNF | 1.265 | 2.756 | 2.756 | 6.5 | 6.5 |

| (127.00) | (311.15) | (6.35) | (76.00) | (74.00) | (32.00) | (32.00) | (54.00) | (53.80) | (18.28) | (32.13) | (70.00) | (70.00) | (165.10) | (165.10) | ||

Data Table

Here we can see importants dimensional datas for TR hydraulic cylinder

| ARTICLE | BORE | STROKE | ROD DIA. | LENGTH | LENGTH | PIN DIA. | PORT | WEIGH | WEIGHT |

| INCH | INCH | INCH | MIN. LENGTH | MAX. LENGTH | INCH | TLBS | KG | ||

| TR2004-112 | 2 | 4 | 1.1/8 | 14.1/4 | 18.1/4 | 1 | 3/8NPT | 14.30 | 6.5 |

| TR2006-112 | 2 | 6 | 1.1/8 | 16.1/4 | 22.1/4 | 1 | 3/8NPT | 15.84 | 7.5 |

| TR2008-112 | 2 | 8 | 1.1/8 | 18.1/4 | 26.1/4 | 1 | 3/8NPT | 17.60 | 8.0 |

| TR2010-112 | 2 | 10 | 1.1/8 | 20.1/4 | 30.1/4 | 1 | 3/8NPT | 18.70 | 8.5 |

| TR2012-112 | 2 | 12 | 1.1/8 | 22.1/4 | 34.1/4 | 1 | 3/8NPT | 20.24 | 9.2 |

| TR2014-112 | 2 | 14 | 1.1/8 | 24.1/4 | 38.1/4 | 1 | 3/8NPT | 22.00 | 10.0 |

| TR2016-112 | 2 | 16 | 1.1/8 | 26.1/4 | 42.1/4 | 1 | 3/8NPT | 23.54 | 10.7 |

| TR2018-112 | 2 | 18 | 1.1/8 | 28.1/4 | 46.1/4 | 1 | 3/8NPT | 25.08 | 11.4 |

| TR2020-112 | 2 | 20 | 1.1/8 | 30.1/4 | 50.1/4 | 1 | 3/8NPT | 26.62 | 12.1 |

| TR2024-112 | 2 | 24 | 1.1/8 | 34.1/4 | 58.1/4 | 1 | 3/8NPT | 28.50 | 12.9 |

| TR2030-112 | 2 | 30 | 1.1/8 | 40.1/4 | 70.1/4 | 1 | 3/8NPT | 31.50 | 14.3 |

| TR2036-112 | 2 | 36 | 1.1/8 | 46.1/4 | 82.1/8 | 1 | 3/8NPT | 33.00 | 15.0 |

| TR2048-112 | 2 | 48 | 1.1/8 | 58.1/4 | 106.1/4 | 1 | 3/8NPT | 35.00 | 15.9 |

| TR2504-112 | 2.5 | 4 | 1.1/8 | 14.1/4 | 18.1/4 | 1 | 3/8NPT | 16.28 | 7.4 |

| TR2506-112 | 2.5 | 6 | 1.1/8 | 16.1/4 | 22.1/4 | 1 | 3/8NPT | 18.04 | 8.2 |

| TR2508-112 | 2.5 | 8 | 1.1/8 | 18.1/4 | 26.1/4 | 1 | 3/8NPT | 20.24 | 9.2 |

| TR2510-112 | 2.5 | 10 | 1.1/8 | 20.1/4 | 30.1/4 | 1 | 3/8NPT | 21.34 | 9.7 |

| TR2512-112 | 2.5 | 12 | 1.1/8 | 22.1/4 | 34.1/4 | 1 | 3/8NPT | 23.10 | 10.5 |

| TR2514-112 | 2.5 | 14 | 1.1/8 | 24.1/4 | 38.1/4 | 1 | 3/8NPT | 24.86 | 11.3 |

| TR2516-112 | 2.5 | 16 | 1.1/8 | 26.1/4 | 42.1/4 | 1 | 3/8NPT | 26.62 | 12.1 |

| TR2518-112 | 2.5 | 18 | 1.1/8 | 28.1/4 | 46.1/4 | 1 | 3/8NPT | 28.38 | 12.9 |

| TR2520-112 | 2.5 | 20 | 1.1/8 | 30.1/4 | 50.1/4 | 1 | 3/8NPT | 30.14 | 13.7 |

| TR2524-112 | 2.5 | 24 | 1.1/8 | 34.1/4 | 58.1/4 | 1 | 3/8NPT | 33.66 | 15.3 |

| TR2530-112 | 2.5 | 30 | 1.1/8 | 40.1/4 | 70.1/4 | 1 | 3/8NPT | 39.66 | 18.0 |

| TR2536-112 | 2.5 | 36 | 1.1/8 | 46.1/4 | 82.1/4 | 1 | 3/8NPT | 38.25 | 17.3 |

| TR2548-112 | 2.5 | 48 | 1.1/8 | 58.1/4 | 106.1/4 | 1 | 3/8NPT | 50.25 | 22.8 |

| TR3004-125 | 3 | 4 | 1.1/4 | 14.1/4 | 18.1/4 | 1 | 1/2NPT | 21.56 | 9.8 |

| TR3006-125 | 3 | 6 | 1.1/4 | 16.1/4 | 22.1/4 | 1 | 1/2NPT | 33.76 | 10.8 |

| TR3008-125 | 3 | 8 | 1.1/4 | 18.1/4 | 26.1/4 | 1 | 1/2NPT | 26.62 | 12.1 |

| TR3010-125 | 3 | 10 | 1.1/4 | 20.1/4 | 30.1/4 | 1 | 1/2NPT | 28.16 | 12.8 |

| TR3012-125 | 3 | 12 | 1.1/4 | 22.1/4 | 34.1/4 | 1 | 1/2NPT | 30.36 | 13.8 |

| TR3014-125 | 3 | 14 | 1.1/4 | 24.1/4 | 38.1/4 | 1 | 1/2NPT | 32.56 | 14.8 |

| TR3016-125 | 3 | 16 | 1.1/4 | 26.1/4 | 42.1/4 | 1 | 1/2NPT | 34.76 | 15.8 |

| TR3018-125 | 3 | 18 | 1.1/4 | 28.1/4 | 46.1/4 | 1 | 1/2NPT | 36.96 | 16.8 |

| TR3020-125 | 3 | 20 | 1.1/4 | 30.1/4 | 50.1/4 | 1 | 1/2NPT | 39.16 | 17.7 |

| TR3024-125 | 3 | 24 | 1.1/4 | 34.1/4 | 58.1/4 | 1 | 1/2NPT | 43.34 | 19.6 |

| TR3030-125 | 3 | 30 | 1.1/4 | 40.1/4 | 70.1/4 | 1 | 1/2NPT | 48.00 | 21.8 |

| TR3036-125 | 3 | 36 | 1.1/2 | 46.1/4 | 82.1/4 | 1 | 1/2NPT | 54.55 | 24.7 |

| TR3048-125 | 3 | 48 | 1.1/2 | 58.1/4 | 106.1/4 | 1 | 1/2NPT | 74.69 | 33.8 |

| TR3504-125 | 3.5 | 4 | 1.1/4 | 14.1/4 | 18.1/4 | 1 | 1/2NPT | 23.32 | 10.6 |

| TR3506-125 | 3.5 | 6 | 1.1/4 | 16.1/4 | 22.1/4 | 1 | 1/2NPT | 25.52 | 11.6 |

| TR3508-125 | 3.5 | 8 | 1.1/4 | 18.1/4 | 26.1/4 | 1 | 1/2NPT | 28.82 | 13.1 |

| TR3510-125 | 3.5 | 10 | 1.1/4 | 20.1/4 | 30.1/4 | 1 | 1/2NPT | 29.92 | 13.6 |

| TR3512-125 | 3.5 | 12 | 1.1/4 | 22.1/4 | 34.1/4 | 1 | 1/2NPT | 32.34 | 14.7 |

| TR3514-125 | 3.5 | 14 | 1.1/4 | 24.1/4 | 38.1/4 | 1 | 1/2NPT | 32.76 | 15.8 |

| TR3516-125 | 3.5 | 16 | 1.1/4 | 26.1/4 | 42.1/4 | 1 | 1/2NPT | 37.18 | 16.8 |

| TR3518-125 | 3.5 | 18 | 1.1/4 | 28.1/4 | 46.1/4 | 1 | 1/2NPT | 39.60 | 17.9 |

| TR3520-125 | 3.5 | 20 | 1.1/4 | 30.1/4 | 50.1/4 | 1 | 1/2NPT | 42.02 | 19.0 |

| TR3524-150 | 3.5 | 24 | 1.1/2 | 34.1/4 | 58.1/4 | 1 | 1/2NPT | 51.07 | 23.1 |

| TR3530-150 | 3.5 | 30 | 1.1/2 | 40.1/4 | 70.1/4 | 1 | 1/2NPT | 55.00 | 24.9 |

| TR3532-150 | 3.5 | 32 | 1.1/2 | 42.1/4 | 74.1/4 | 1 | 1/2NPT | 58.00 | 26.3 |

| TR3536-150 | 3.5 | 36 | 1.1/2 | 46.1/4 | 82.1/4 | 1 | 1/2NPT | 62.00 | 28.1 |

| TR3548-150 | 3.5 | 48 | 1.1/2 | 58.1/4 | 106.1/4 | 1 | 1/2NPT | 74.69 | 33.8 |

| TR4004-125 | 4 | 4 | 1.1/4 | 14.1/4 | 18.1/4 | 1 | 1/2NPT | 29.48 | 13.4 |

| TR4006-125 | 4 | 6 | 1.1/4 | 16.1/4 | 22.1/4 | 1 | 1/2NPT | 33.60 | 15.2 |

| TR4008-125 | 4 | 8 | 1.1/4 | 18.1/4 | 26.1/4 | 1 | 1/2NPT | 35.16 | 15.9 |

| TR4010-125 | 4 | 10 | 1.1/4 | 20.1/4 | 30.1/4 | 1 | 1/2NPT | 37.84 | 17.1 |

| TR4012-125 | 4 | 12 | 1.1/4 | 22.1/4 | 34.1/4 | 1 | 1/2NPT | 40.70 | 18.4 |

| TR4014-125 | 4 | 14 | 1.1/4 | 24.1/4 | 38.1/4 | 1 | 1/2NPT | 43.56 | 19.7 |

| TR4016-125 | 4 | 16 | 1.1/4 | 26.1/4 | 42.1/4 | 1 | 1/2NPT | 46.42 | 21.0 |

| TR4018-150 | 4 | 18 | 1.1/2 | 28.1/4 | 46.1/4 | 1 | 1/2NPT | 50.60 | 22.9 |

| TR4020-150 | 4 | 20 | 1.1/2 | 30.1/4 | 50.1/4 | 1 | 1/2NPT | 53.46 | 24.2 |

| TR4024-150 | 4 | 24 | 1.1/2 | 34.1/4 | 58.1/4 | 1 | 1/2NPT | 59.18 | 26.8 |

| TR4024-200 | 4 | 24 | 2 | 34.1/4 | 58.1/4 | 1 | 1/2NPT | 68.00 | 30.8 |

| TR4030-175 | 4 | 30 | 1.3/4 | 40.1/4 | 70.1/4 | 1 | 1/2NPT | 75.00 | 34.0 |

| TR4030-200 | 4 | 30 | 2 | 40.1/4 | 70.1/4 | 1 | 1/2NPT | 78.00 | 35.3 |

| TR4036-175 | 4 | 36 | 1.3/4 | 46.1/4 | 82.1/4 | 1 | 1/2NPT | 82.00 | 37.2 |

| TR4040-175 | 4 | 40 | 1.3/4 | 50.1/4 | 86.1/4 | 1 | 1/2NPT | 90.00 | 40.8 |

| TR4048-175 | 4 | 48 | 1.3/4 | 58.1/4 | 94.1/4 | 1 | 1/2NPT | 98.00 | 44.4 |

| TR5004-150 | 5 | 4 | 1.1/2 | 16.1/4 | 16.1/4 | 1 | 1/2NPT | 53.46 | 24.2 |

| TR5006-150 | 5 | 6 | 1.1/2 | 18.1/4 | 18.1/4 | 1 | 1/2NPT | 56.76 | 25.7 |

| TR5008-150 | 5 | 8 | 1.1/2 | 20.1/4 | 20.1/4 | 1 | 1/2NPT | 61.16 | 27.7 |

| TR5010-150 | 5 | 10 | 1.1/2 | 22.1/4 | 32.1/4 | 1 | 1/2NPT | 63.36 | 28.7 |

| TR5012-200 | 5 | 12 | 2 | 24.1/4 | 34.1/4 | 1 | 1/2NPT | 73.04 | 33.1 |

| TR5014-200 | 5 | 14 | 2 | 26.1/4 | 40.1/4 | 1 | 1/2NPT | 77.00 | 34.9 |

| TR5016-200 | 5 | 16 | 2 | 28.1/4 | 44.1/4 | 1 | 1/2NPT | 81.18 | 36.8 |

| TR5018-200 | 5 | 18 | 2 | 30.1/4 | 48.1/4 | 1 | 1/2NPT | 85.14 | 38.6 |

| TR5020-200 | 5 | 20 | 2 | 32.1/4 | 52.1/4 | 1 | 1/2NPT | 89.10 | 40.4 |

| TR5024-200 | 5 | 24 | 2 | 36.1/4 | 60.1/4 | 1 | 1/2NPT | 97.24 | 44.1 |

| TR5030-200 | 5 | 30 | 2 | 42.1/4 | 72.1/4 | 1 | 1/2NPT | 109.56 | 49.7 |

| TR5036-225 | 5 | 36 | 2.1/4 | 46.1/4 | 84.1/4 | 1 | 1/2NPT | 163.00 | 73.9 |

| TR5048-225 | 5 | 48 | 2.1/4 | 60.1/4 | 108.1/4 | 1 | 1/2NPT | 186.00 | 84.3 |

Get Your Tie Rod Hydraulic Cylinders Today!

Call us or visit our website to get more information about the hydraulic cylinders you need.

Material

We Always Use Good Quality Material For Our TR Cylinders

- ROD:Hard chrome plated.

- TUBE:Precision honed steel for extended seal life. Tie-rods: Heavy duty, high strength.

- GLAND:Ductile iron.

- PISTON:Steel.

- END MOUNTS:Ductile Iron female clevis with pins and clips included.

- PORTS:NPT,NPTF&SAE is available.

- SEALS:Hallite.

- PAINT:Black(STD), color and other custom colors are available.

- ROD ENDS:Ductile Iron female clevis with pins and clips included.

Production Processes

How We Produce TR Hydraulic Cylinders

Our Factory

Our Factory

OEM Custom Service is Available

Customized Solutions for Your Hydraulic Needs

There are a handful of different types of cylinders for different industries, but no matter which type you need, even custom welded hydraulic cylinders, AiSoar can provide them.

OEM Tie-Rod Hydraulic Cylinder

Our OEM Tie Rod Hydraulic Cylinders are engineered with precision and attention to detail. We work closely with you to understand your specific needs, whether it's a particular bore size, stroke length, or pressure rating. We take your requirements and turn them into a hydraulic solution that fits like a glove.

Customized Service

The TR series tie rod cylinder is the standard type, but customized strokes, intergraded valves, and special tube and rod materials are available.Our commitment to excellence means we use only the finest materials, ensuring durability and performance in the toughest conditions,besides, AiSoar engineers aren't just skilled; they're problem solvers, dedicated to turning your challenges into successful hydraulic solutions.We understand that time is of the essence. Our streamlined processes ensure quick delivery without compromising on quality.

FAQ

Frequently Asked Questions

We'll try to answer some of your questions

A:AiSoar TR series tie-rod hydraulic cylinders have been widely used in agricultural, trailer and loader industry. For agricultural equipment, trailer, loader, generally include the lift moving system, the hydraulic cylinder should be fixed into positon, then to move in the shape of an arc during extension and retraction. The TR cylinders with clevis mounted, are typically a good solution in the applications.

A: Definitely yes, we have our own factory. We would like to show you videos via WhatsApp or Wechat.

A: 1" pin hole for bore size 1"~4", and 1.25" pin hole for bore size 5".

A: Yes, it's a rebuild-able cylinder and we do offer repair kits. Tie rod type is easy to repair.

A: Retracted length from center pin to center pin, we also call out min. length or closed length. Extended length is the retracted on centers plus the stroke, we also call out max. length or open length.

A:Rigid quality standards & control on raw materialsare always implemented in AiSoar hydraulics. We have really stable suppliers with long-term cooperative relationship. We inspection for each batch of incoming goods, and review our supplier quality performance by year.

A:Firstly, We should determine the technical parameter first: bore size, rod size, stroke, working pressure, required force (Column Load).

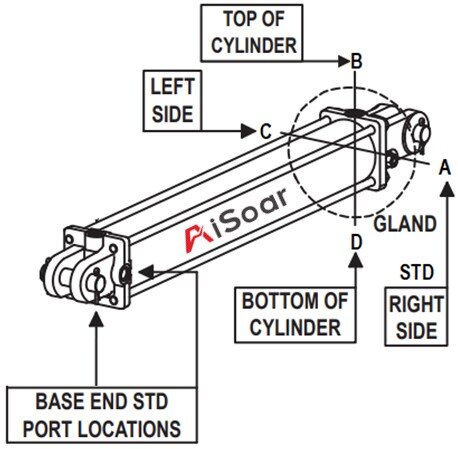

How to Measure Hydraulic Cylinder

Secondly, check the drawings’sizes carefully, especially the mounting sizes, include the distance of clevis, gland port location as below pic shows, and etc.

(Port location determined from viewing cylinder from base end)

Others information: Port style and size, painting, clevis pin installation and retainer options, package.

Aisoar Hydraulic Cylinders Catalogue

The tie-rod cylinders with clevis mounted both rod ends and base ends, we call out TR series. AiSoar tie rod cylinders, available in a variety of bore and stroke sizes, bore size ranges from 2 to 5 inches, stroke ranges from 4 to 48 inches, working pressure ranges from 2500PSI to 3000PSI.

DownloadGet a Quote Now

ANYTHING YOU COULDN'T FIND?

Talk with one of our sales representatives

Hydraulic Cylinder Manufacturer? Contact Immediately For Consultation.

Send us an email

Contact Us

Have any question about our AiSoar Hydraulic?Please contact us and we will get back to you immediately.

ES

ES RU

RU