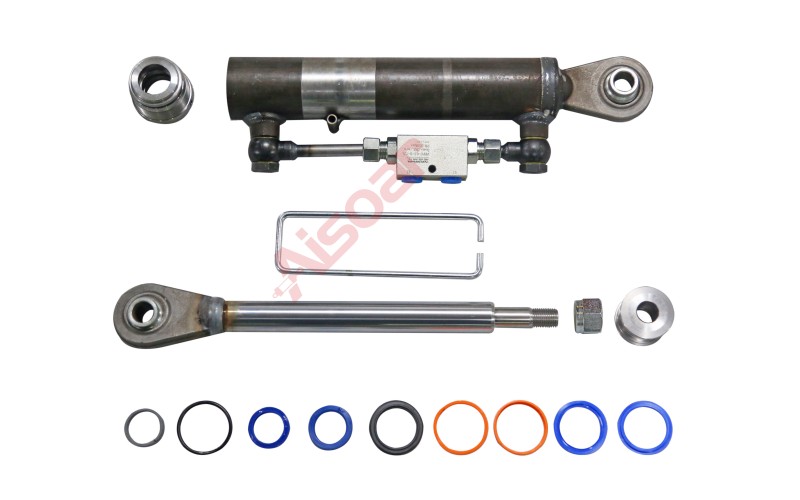

STANDARD HYDRAULIC TOP LINK WITH FIXED EYE

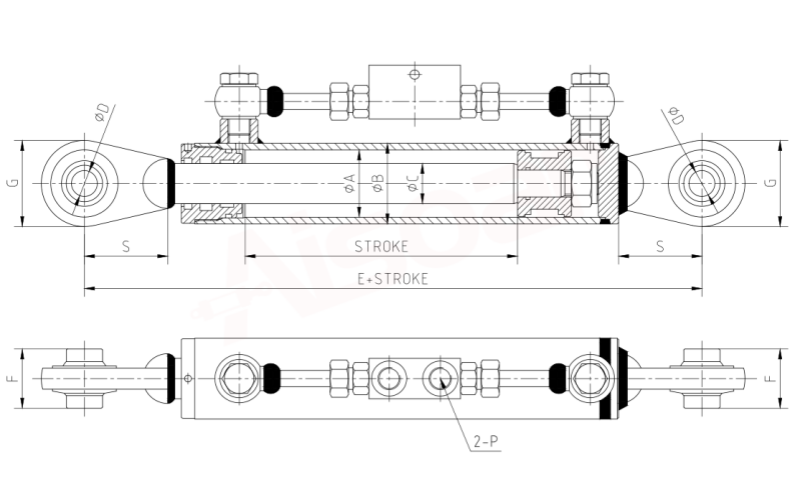

Detailed Drawing

Modle Code System

Standard Hydraulic Top Link With Ball Joint Drawing

Standard Hydraulic Top Link With Ball Joint Drawing

We can check the main sizes in below drawing

| ΦA(BORE) | E | ΦB | ΦC | ΦD | F | G | S | P |

| 50 | 250 | 60 | 30 | 19.3 | 44 | 62 | 62 | G3/8 |

| 50 | 270 | 60 | 30 | 25.4 | 51 | 75 | 65 | G3/8 |

| 60 | 280 | 70 | 35 | 25.4 | 51 | G3/8 | ||

| 80 | 310 | 95 | 40 | 25.4 | 51 | G3/8 |

Data Table

Here we can see importants dimensional datas for Top Link cylinders

| Order Code | ΦA | ΦB | ΦC | Stroke | E+Stroke | ΦD | F | G | P | S | Thrust t @2600PSI | Lift t @2600PSI | Vol(Liter) | Weight(Kg) |

| WTL-FE50×30×160-410 | 50 | 60 | 30 | 160 | 410 | 19.3 | 44 | 62 | G3/8" | 62 | 3.5 t | 2.3 t | 0.32 | 5.60 |

| WTL-FE50×30×210-460 | 210 | 460 | 19.3 | 0.42 | 6.20 | |||||||||

| WTL-FE50× 30×280-530 | 280 | 530 | 19.3 | 0.56 | 7.10 | |||||||||

| WTL-FE50×30×400-650 | 400 | 650 | 19.3 | 0.8 | 8.50 | |||||||||

| WTL-FE50×30×160-430 | 160 | 430 | 25.4 | 51 | 75 | 65 | 0.32 | 6.30 | ||||||

| WTL-FE50×30×210-480 | 210 | 480 | 25.4 | 0.42 | 6.90 | |||||||||

| WTL-FE50×30×280-550 | 280 | 550 | 25.4 | 0.56 | 7.90 | |||||||||

| WTL-FE50×30×400-670 | 400 | 670 | 25.4 | 0.8 | 9.20 | |||||||||

| WTL-FE60×35×160-440 | 60 | 70 | 35 | 160 | 440 | 25.4 | 5.1 t | 3.3 t | 0.48 | 7.80 | ||||

| WTL-FE60×35×210-490 | 210 | 490 | 25.4 | 0.63 | 8.60 | |||||||||

| WTL-FE60×35×280-560 | 280 | 560 | 25.4 | 0.84 | 9.60 | |||||||||

| WTL-FE60×35×400-680 | 400 | 680 | 25.4 | 1.2 | 15.60 | |||||||||

| WTL-FE80×40×160-450 | 80 | 90 | 40 | 160 | 450 | 25.4 | 9.0 t | 6.8 t | 0.9 | 12.50 | ||||

| WTL-FE80×40×210-500 | 210 | 500 | 25.4 | 1.2 | 13.70 | |||||||||

| WTL-FE80×40×280-570 | 280 | 570 | 25.4 | 1.6 | 15.20 | |||||||||

| WTL-FE80×40×400-690 | 400 | 690 | 25.4 | 2.2 | 18.00 |

Get Your Top Link HYDRAULIC CYLINDER Today!

Call us or visit our website to get more information about the hydraulic cylinders you need.

Material

We Always Use Good Quality Material For Our Top Link Cylinders

- Working pressure: 180 bars.

- Working temperature: -25ºC - +80ºC

- Speed: 0.5 m/s.

- Oil: Mineral oil.

- Rod: C45 f7 25 microns.

- Tube: C1020, H9.

- GLAND: C1045 Steel.

- PISTON: C1045 Steel.

- SEALS: Hallite.

- PORTS: G3/8.

- Banjo Bolt:G3/8 .

- Washer:G3/8

- Valve: Twin-type non-return valve

- PAINT: Black(STD), color and other custom colors are available.

- Hose:730mm length, G1/2, G3/8 Male couplers with dust cover

Production Processes

How We Produce Top Link Hydraulic Cylinders

Our Factory

Our Factory

OEM Custom Service is Available

What Kind Of Cylinders Do You Need?

OEM Top Link Hydraulic Cylinder

A Custom Standard Hydraulic Top Link with Fixed Eye is a specialized hydraulic cylinder designed for agricultural machinery applications,such as tractor. Here's a general process:

Requirement Gathering:

Determine the specific needs of the machinery or application, including the required length, diameter, and stroke of the hydraulic top link.Understand the load capacity and pressure ratings needed based on the tasks the top link will be performing.

Design Specifications:

Decide on the fixed eye design, including the size and type of eye needed for the connection points.

Specify materials that will offer the required strength and durability, considering factors like corrosion resistance and exposure to various environmental conditions.

Engineering and CAD Modeling:

AiSoar use computer-aided design (CAD) software to create detailed models of the top link. This step is crucial for visualizing the final product and making precise calculations.

Perform simulations if necessary to test the strength and functionality of the design under various load conditions.

Top Link Hydraulic Cylinder For Tractor

Engineering and CAD Modeling:

AiSoar use computer-aided design (CAD) software to create detailed models of the top link. This step is crucial for visualizing the final product and making precise calculations.

Perform simulations if necessary to test the strength and functionality of the design under various load conditions.

Custom Fabrication:

Based on the design, fabricate the cylinder body, piston, and rod. This might involve machining processes like turning, milling, and welding.

Ensure that the fixed eye ends are robustly attached and capable of withstanding the forces they will encounter.

Assembly and Testing:

Assemble the hydraulic top link, including installing seals and filling with hydraulic fluid.

Conduct rigorous testing to check for leaks, ensure proper operation, and verify that it meets the load and pressure specifications.

FAQ

Frequently Asked Questions

A: Yes, we have several sizes in stock; you can tell me your specification, if the specification you need is in stock, we can ship immediately!

A: There is currently a deal in shop and this price includes ×2 hoses, Male couplers with dust cover, banjo bolts and washers

A: Sure. You provides the drawing, and we can customize it for you.

A: Yes, we do. We can design the custom cylinder, build it, supply it and solve it worldwide!

A: Well, it quite depends on the quantity or the style of hydrualic cylinder. In most cases, 4~6 weeks for the first order, and we are able to shorten the lead time for the old order.

Get a Quote Now

ANYTHING YOU COULDN'T FIND?

Talk with one of our sales representatives

Hydraulic Cylinder Manufacturer? Contact Immediately For Consultation.

Send us an email

Contact Us

Have any question about our AiSoar Hydraulic?Please contact us and we will get back to you immediately.

ES

ES RU

RU