When to Repair vs. Replace a Hydraulic Cylinder

Typical Signs of Hydraulic Cylinder Malfunction That Must Not Be Overlooked

Odd Noises (Banging or Knocking) Banging or knocking sounds emanating from hydraulic cylinders typically signify significant issues. These noises often point to two primary problems:

Aeration: This issue arises when air gets into the system via leaky intake lines. The air bubbles created then compress and decompress during circulation, producing a noticeable clanging sound.

Cavitation: This occurs when parts of the system experience a fluid deficit. As the pressure decreases, the fluid vaporizes and then implodes when the pressure increases, resulting in loud thumping noises.

Both conditions can cause overheating, damage to seals, and a loss of lubrication. Although these problems might start minor, they can rapidly progress to significant damage to the system if not addressed.

Should you detect any unusual sounds from your hydraulic cylinders, it’s imperative to examine the system promptly. Regular maintenance, such as inspecting intake lines and checking fluid levels, can aid in preventing these issues and extend the durability of your hydraulic system.

Stuttering or Irregular Motion "If the movement of your hydraulic cylinder is stuttering or irregular, it's a definite indicator of a problem. Often referred to as 'juddering,' this issue manifests when the cylinder moves in a staggered manner as it extends.

Juddering is commonly a result of heightened friction, deteriorated seals, inadequate lubrication, or even a misshapen rod. These complications can also lead to the cylinder overheating, consuming more energy to function, and diminishing its efficiency."

A faulty hydraulic cylinder might be to blame. When internal or external leaks are present and friction increases, the system requires more power to operate effectively. This demands more effort from the hydraulic pumps, which need to supply extra fluid to compensate for the leakage.

Elevated Energy Usage

Have you seen a rise in your power expenses?

A faulty hydraulic cylinder might be to blame. When internal or external leaks are present and friction increases, the system requires more power to operate effectively. This demands more effort from the hydraulic pumps, which need to supply extra fluid to compensate for the leakage.

Deceleration of the Actuator

If your hydraulic cylinder is decelerating and diminishing in power, it’s a significant indicator of issues. This power reduction is frequently caused by escalated friction or internal leakage. When internal leakage happens, the cylinder requires additional time to accumulate the needed pressure, thus delaying the operation.

Many operators may attempt to compensate for this by boosting the power, but this merely conceals the actual problem. The performance of the cylinder will persist in deteriorating until it ultimately fails, since the fundamental issue is left unaddressed.

Excessive Heat

Manufacturers set precise standards for the acceptable operating temperatures of hydraulic cylinders. When your cylinder surpasses these temperature thresholds, it’s a definite indication of an underlying problem with the system’s heat regulation capabilities.

Overheating may arise from too much friction among moving components, tainted fluid, insufficient fluid quantities, or poor oil filtration. Overlooking these indicators can result in severe damage.

Irregular Piston Rod Wear

Hydraulic cylinders are engineered for linear motion, meaning the wear on the piston rod should be even.

Observing disproportionate wear on one side of the rod is a clear sign of trouble. Potential causes include misalignment, a deformed rod, excessive side loading, or internal harm. Conducting regular inspections of your piston rods for irregular wear can help avert more extensive and expensive problems.

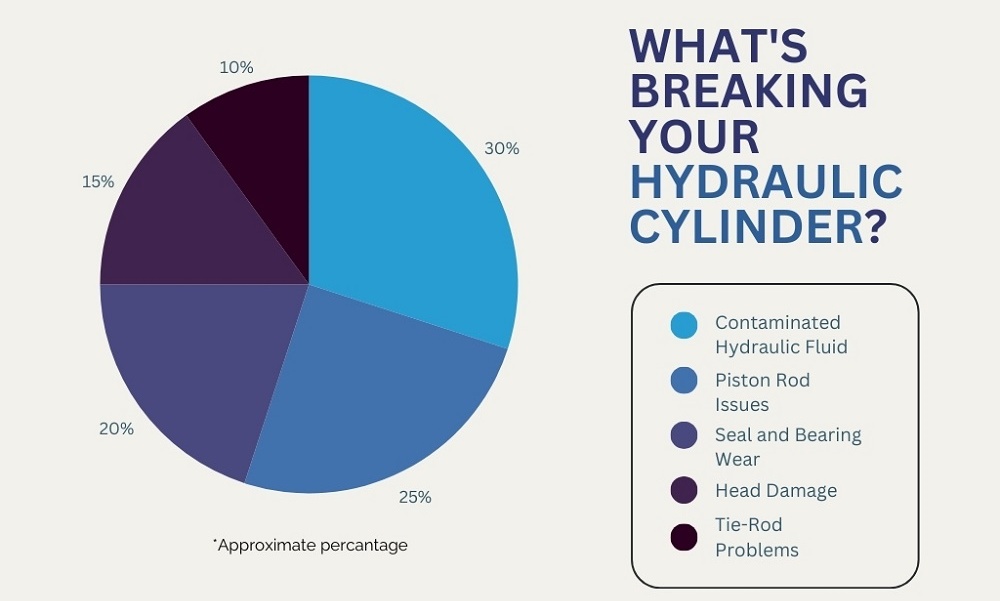

Common Causes of Hydraulic Cylinder Failure

Should I Repair or Replace a Hydraulic Cylinder?

| Type | Replace | Repair |

Exceeded Cylinder's Life Expectancy | √ | |

| Old Cylinder of Replacement Parts | √ | |

| Older Cylinders be Discontinued | √ | |

| Small Isolated Problem to Failure | √ | |

| Minor Damage | √ | |

| Extensive Damage or Structural Issues | √ |

If you've decided to go ahead and repair a hydraulic cylinder, it's very important to know how to do it

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU