What is the Difference Between Single Acting and Double Acting Hydraulic Cylinder?

Struggling to choose the right hydraulic cylinder? The wrong choice can lead to inefficiency, equipment failure, and costly downtime. Understanding the difference between single acting and double acting cylinders can help you make the best decision.

A single acting hydraulic cylinder uses pressure to move in one direction, while a double acting hydraulic cylinder moves in both directions, offering more control. The choice between them depends on the specific requirements of your application.

Want to dive deeper into the workings and applications of these cylinders? Keep reading to understand their differences and advantages.

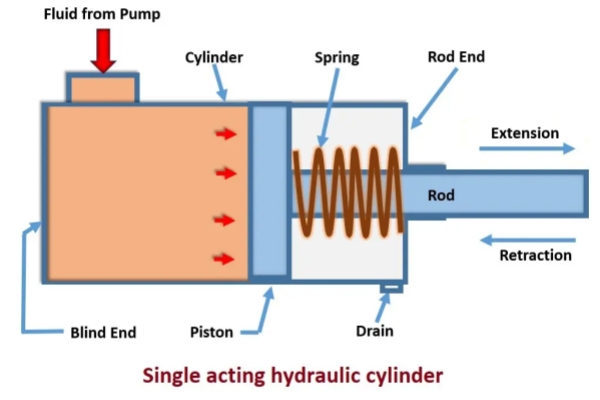

What's a Single Acting Hydraulic Cylinder?

A single acting hydraulic cylinder is a type of hydraulic actuator that moves in one direction using hydraulic pressure. It relies on a spring or gravity to return to its starting position after the pressure is released. This type of cylinder is often used in applications where only one-way movement is needed, such as lifting a load in a vertical position. It's simpler and more cost-effective, but it doesn’t provide the same level of control as a double acting cylinder.

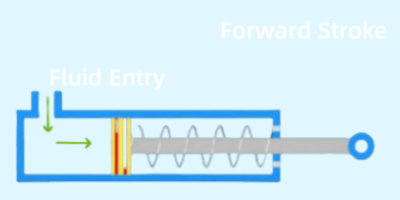

How Does a Single Acting Hydraulic Cylinder Work?

A single acting hydraulic cylinder works by applying pressure to one side of a piston. The pressure pushes the piston in one direction, and once the pressure is released, the piston is returned by a spring or gravitational force. This makes it an ideal choice for operations where the load only needs to move in one direction, such as in dump trucks or construction machinery.

What Are the Applications of a Single Acting Hydraulic Cylinder?

Single acting hydraulic cylinders are used in various applications, including snowplows, dump trucks, and hydraulic jacks. In a snowplow, for example, the cylinder is used to raise and lower the plow blade. Once the hydraulic pressure is released, the spring returns the blade to its original position. This one-way movement is all that’s needed for many such machines, making single acting cylinders an effective and affordable option.

What Are the Pros and Cons of a Single Acting Hydraulic Cylinder?

| Pros | Cons |

| Simple design and cost-effective | Limited to one-way movement |

| Requires less hydraulic fluid | Less control over the return stroke |

| Ideal for applications with low frequency of use | Not suitable for complex or high-demand operations |

What's a Double Acting Hydraulic Cylinder?

A double acting hydraulic cylinder is a more versatile type of actuator that uses hydraulic pressure to move the piston in both directions. This means it can exert force both when extending and retracting. The cylinder has two ports for hydraulic fluid—one for each direction of movement—offering greater control and precision compared to single acting cylinders. This is ideal for applications that require more complex movements.

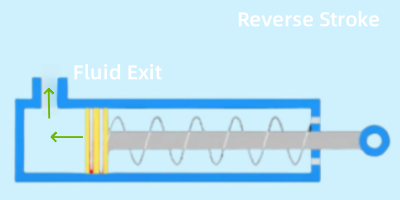

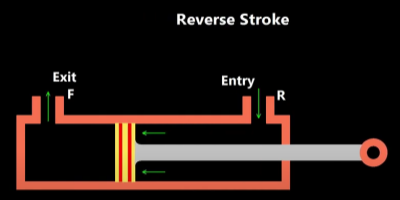

How Does a Double Acting Hydraulic Cylinder Work?

A double acting hydraulic cylinder uses hydraulic pressure on both sides of the piston, enabling it to move in both directions. The cylinder has two separate hydraulic lines: one for the extend function and one for the retract function. When pressure is applied to one side, the piston extends, and when pressure is applied to the other side, the piston retracts. This gives the operator more control over both directions of movement, making it suitable for applications requiring precision and repetitive motions.

What Are the Applications of a Double Acting Hydraulic Cylinder?

Double acting hydraulic cylinders are widely used in industrial equipment, construction machinery, and material handling systems. For example, in a hydraulic press, the cylinder provides controlled movements in both directions to apply and release force. Similarly, they are often found in applications such as steering mechanisms in vehicles, where precise movement in both directions is critical for functionality.

Compare Single Acting with Double Acting

| Feature | Single Acting Hydraulic Cylinder | Double Acting Hydraulic Cylinder |

| Direction of Movement | One-directional movement | Bi-directional movement |

| Complexity | Simple and less complex | More complex due to two ports for fluid |

| Control | Limited control over return stroke | Precise control over both directions |

| Applications | Suitable for simple, one-way applications | Ideal for high-precision and repetitive tasks |

| Cost | More affordable | Generally more expensive |

Summary

Choosing between single and double acting cylinders depends on the application needs, control required, and budget constraints.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU