What is a ram type hydraulic cylinder?

What is a Hydraulic Ram?

Hydraulic Ram: Not Your Average Plumbing Tool

You might think hydraulic rams are just fancy plumbing tools for industrial facilities, but these clever contraptions do so much more! A hydraulic ram is essentially a cylinder with a movable rod that can, you guessed it, move stuff around. Whether it’s shifting massive rocks on a construction site or helping an amusement park ride come to life, hydraulic rams are the unsung heroes of machinery.

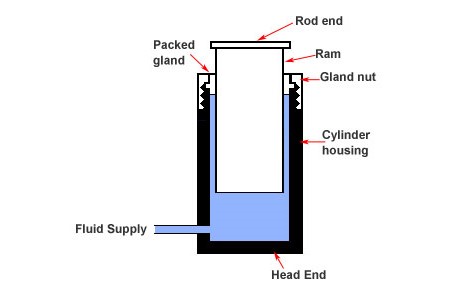

Ram type hydraulic cylinders are considered to be a type of hydraulic actuator. A ram cylinder is a hydraulic cylinder that acts as a ram. Hydraulic cylinder is a device whose piston rod cross-sectional area is more than half the cross-sectional area of moving parts.

How Does a Hydraulic Ram Work? Just Add Fluid and… Boom!

Okay, here’s where things get a little tricky, but don’t worry—we’ll break it down.

At its core, a hydraulic ram works by using pressurized fluid to move a rod inside a cylinder. Here’s how it functions in simple terms:

Fluid Goes In: A hydraulic ram works by pumping fluid into either side of a cylinder at the same time. The fluid creates a high-pressure side and a low-pressure side. It’s like the cylinder’s way of saying, “Hey, I’m strong, but I can also be chill when I need to be.”

Pressure Makes the Magic: Depending on how much force is needed to move a load, the ram uses that high pressure to do its heavy lifting (literally). Think of it as a giant pushing machine powered by hydraulic energy.

Rod Moves, Job Gets Done: Fluid is pumped through ports to extend or retract the rod. Push fluid in one way, the rod moves out (and does the work). Push it in the opposite way, the rod moves back in, ready to do it all over again. It’s like a giant piston party every time!

What’s Inside a Hydraulic Ram? A Mystery of Simple Components

Cylinder Tube: The heavy-duty housing that keeps everything in check.

Piston: The heart of the system, moving fluid around and creating pressure.

Rod: The mechanical arm that does the heavy lifting.

Gland: The protector of the rod (don’t worry, it’s not as complicated as it sounds).

Cylinder Ports: The little gateways where fluid enters and exits.

End Caps: These keep everything contained and secure. Seals that close the cylinder and prevent fluid leaks.

And don’t forget—there’s a little bit of science and fluid dynamics going on, too. In a nutshell: fluid goes in, pressure builds up, rod moves, magic happens!

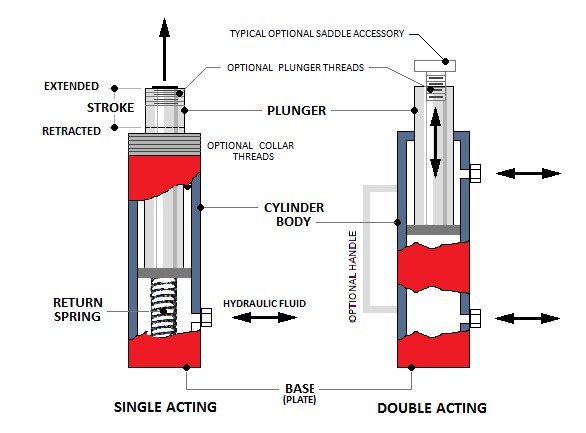

Single Acting Ram Type of Hydraulic Cylinder

A single-acting ram cylinder uses hydraulic pressure to extend its piston and ram rod in one direction, relying on external force for retraction.Single-acting ram cylinders operate based on hydraulic pressure applied to one side of the piston.The hydraulic pressure forces the piston and plunger rod to extend in one direction to retract the ram rod, an external force, such as a spring, gravity, or the resistance of the load being moved, is used

Double Acting Ram Type Of Hydraulic Cylinder

A double-acting ram type hydraulic cylinder is a specific type of hydraulic actuator that operates in both directions, allowing for controlled extension and retraction of the ram or rod using hydraulic pressure. Double-acting ram cylinders use hydraulic pressure on both sides of the piston. Pressure extends the cylinder ram in one direction, and reversing pressure retracts the ram in the opposite direction.

Telescopic Ram Type Hydraulic Cylinder

A telescopic ram type hydraulic cylinder is a specialized hydraulic actuator that combines the characteristics of a ram-type cylinder with a telescopic design.

This type of ram cylinder design and construction are quite complex, these rams are installed in an assembly of telescopic design.

What on Earth Are Hydraulic Rams Used For?

Ram cylinders are used in a wide range of applications, from industrial machines to heavy equipment. Some common uses include:

- Excavators and Diggers: Used for lifting, digging, and maneuvering heavy loads.

- Agricultural Equipment: Common in tractors and other farming machinery to lift heavy items.

- Food Processing: Used in packaging machines to apply force to containers.

- Automotive and Marine Industries: Applied in vehicle lifts, steering systems, and more.

- Construction and Mining: Helps operate heavy-duty machines such as cranes, drills, and loaders.

Conclusion: Why Choose a Hydraulic Ram?

Hydraulic rams are essential in many industries due to their ability to generate large amounts of force with precise control. They are widely used in construction, agriculture, automotive, and manufacturing, making them a cornerstone of modern machinery. Whether lifting, digging, or pushing, a hydraulic ram is a versatile and reliable tool in any operation.

As a Quality Hydraulic Cylinder Manufacturer and Supplier in China, Aisoar Hydraulics is willing to grow with all partners, and to support partners in every possible way we can.

If you have any further questions about hydraulic cylinders, please contact email: alice@ai-soar.com.

|

AISOAR HYDRAULIC CYLINDERS |

ES

ES RU

RU