What Causes Hydraulic Cylinders to Lose Pressure?

Introduction

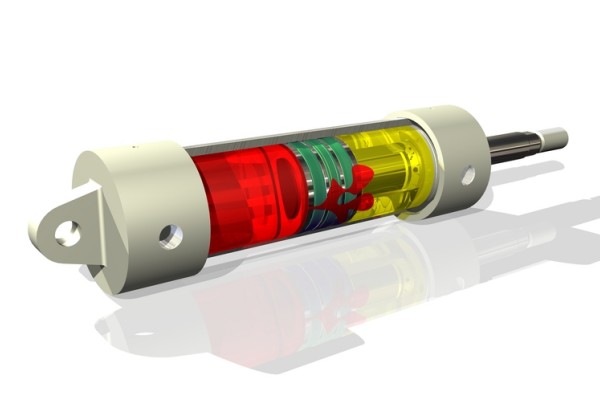

Hydraulic cylinders may lose pressure due to internal or external leaks, affecting system efficiency. Internal leaks often result from worn or damaged seals, piston rings, or barrel surfaces, allowing fluid bypass. External leaks occur at connections, fittings, or rod seals, leading to fluid loss and reduced pressure. Contaminated hydraulic fluid can cause abrasive wear, exacerbating seal damage. Temperature fluctuations may degrade seal materials, compromising their integrity. Additionally, air trapped within the system disrupts pressure consistency. Regular maintenance, proper seal selection, and fluid cleanliness are key to preventing pressure loss and ensuring optimal cylinder performance.

Hydraulic cylinders are vital components in numerous industrial and mobile applications, providing the necessary force for lifting, pushing, pulling, and other mechanical movements. However, one common issue that can arise is the loss of pressure within the hydraulic cylinder, leading to decreased performance and potential system failure. Understanding the causes of pressure loss is crucial for maintaining the efficiency and reliability of your hydraulic systems. In this article, we will explore the primary reasons hydraulic cylinders lose pressure and how to address these issues.

1. Worn or Damaged Seals

Cause: Seals within the hydraulic cylinder prevent fluid from leaking out of the system. Over time, these seals can wear out, crack, or become damaged due to friction, heat, and contamination, leading to internal or external leaks.

Solution: Regularly inspect seals for signs of wear and damage. Replace worn or damaged seals promptly to maintain proper pressure levels.

2. Contaminated Hydraulic Fluid

Cause: Dirt, debris, and other contaminants in the hydraulic fluid can cause abrasion and damage to seals and internal surfaces, leading to leaks and pressure loss. Contaminated fluid can also clog filters and restrict fluid flow.

Solution: Use high-quality hydraulic fluid and change it according to the manufacturer's recommendations. Regularly check and replace filters to keep the fluid clean and free of contaminants.

3. Cylinder Barrel or Rod Damage

Cause: Scratches, dents, or corrosion on the cylinder barrel or rod can create paths for fluid to escape, resulting in pressure loss. Such damage can be caused by external impacts, improper handling, or environmental factors.

Solution: Inspect the cylinder barrel and rod for any signs of damage. If damage is found, repair or replace the affected components. Implement protective measures to prevent future damage.

4. Improper Assembly or Installation

Cause: Incorrect assembly or installation of the hydraulic cylinder can lead to misalignment, improper seal compression, and loose connections, all of which can contribute to pressure loss.

Solution: Ensure that hydraulic cylinders are assembled and installed according to the manufacturer's specifications. Double-check the alignment and tightness of all connections during installation.

5. Internal Leakage

Cause: Internal leakage within the cylinder can occur when fluid bypasses the piston seals. This can happen due to worn seals, damaged piston rods, or excessive clearances between components.

Solution: Inspect the piston seals and rod for wear or damage. Replace faulty seals and components to prevent internal leakage. Regularly maintain the cylinder to keep internal components in good condition.

6. Temperature Fluctuations

6. Temperature Fluctuations

Cause: Extreme temperature fluctuations can affect the viscosity of the hydraulic fluid and the elasticity of seals, leading to leaks and pressure loss. Cold temperatures can cause seals to harden and shrink, while high temperatures can cause them to soften and degrade.

Solution: Use hydraulic fluid that is suitable for the operating temperature range of your application. Consider using temperature-resistant seals if operating in extreme conditions. Monitor and control the operating environment to minimize temperature fluctuations.

7. Overloaded Cylinders

Cause: Operating a hydraulic cylinder beyond its rated capacity can cause excessive wear and stress on seals and other components, leading to pressure loss and potential failure.

Solution: Ensure that hydraulic cylinders are used within their specified load limits. Avoid overloading and perform regular maintenance checks to identify signs of excessive wear.

Conclusion

Hydraulic cylinder pressure loss can significantly impact the performance and efficiency of your hydraulic systems. By understanding the common causes and implementing preventative measures, you can maintain the reliability and longevity of your hydraulic cylinders. Regular inspections, proper maintenance, and using high-quality components and fluids are essential steps in preventing pressure loss and ensuring optimal operation of your hydraulic systems.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU