Why Does The Hydraulic Cylinder Make A Clicking Sound And How to Fix It?

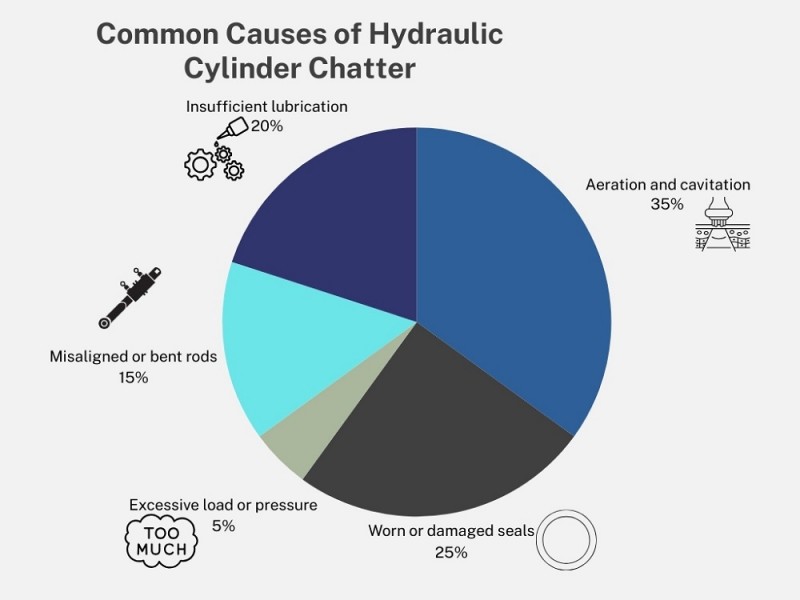

What Causes a Hydraulic Cylinder to Chatter?

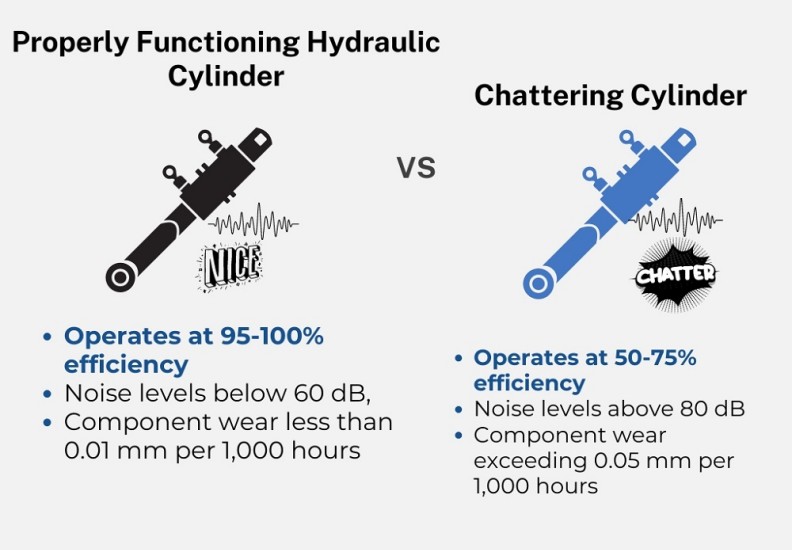

Hydraulic cylinders are critical components in various industrial and mobile applications, providing the necessary force to perform tasks ranging from lifting heavy loads to precise control in manufacturing processes. However, one common issue that can affect hydraulic cylinders is "chattering." This phenomenon can lead to performance degradation, increased wear, and potential system failure if not addressed promptly. In this article, we will explore the primary causes of hydraulic cylinder chatter and how to diagnose and mitigate these issues effectively.

Understanding Hydraulic Cylinder Chatter

Hydraulic cylinder chatter is characterized by a rapid, repetitive motion or vibration of the cylinder, which can cause noise and affect the smooth operation of the system. It is typically a symptom of underlying problems within the hydraulic system. Here are some common causes of hydraulic cylinder chatter:

1. Air in the Hydraulic System

Cause: Air trapped in the hydraulic fluid can compress and decompress rapidly, causing erratic movement and chatter.

Diagnosis: Check for foamy hydraulic fluid, inconsistent cylinder movement, or hissing sounds during operation.

Solution: Bleed the hydraulic system to remove trapped air. Ensure all connections are tight and there are no leaks allowing air to enter the system.

2. Contaminated Hydraulic Fluid

Cause: Dirt, debris, and other contaminants in the hydraulic fluid can cause blockages and irregular flow, leading to chattering.

Diagnosis: Inspect the hydraulic fluid for discoloration, particles, or sludge. Monitor the performance for irregular movements.

Solution: Regularly filter and replace hydraulic fluid according to the manufacturer's recommendations. Use high-quality hydraulic fluid and ensure clean handling practices.

3. Worn or Damaged Seals

Cause: Worn or damaged seals can cause internal leakage, leading to inconsistent pressure and movement, resulting in chatter.

Diagnosis: Look for external hydraulic fluid leaks, reduced performance, and irregular cylinder movement.

Solution: Inspect and replace damaged or worn seals. Regular maintenance can help identify seal issues before they lead to significant problems.

4. Improperly Sized or Worn Components

Cause: Incorrectly sized components or worn internal parts can lead to misalignment and uneven force distribution, causing chattering.

Diagnosis: Check for uneven wear patterns on cylinder components and ensure all parts are within specification.

Solution: Replace worn or improperly sized components. Ensure proper sizing and alignment during installation and maintenance.

5. Inadequate Hydraulic Fluid Flow

Cause: Insufficient fluid flow due to clogged filters, restricted hoses, or undersized pumps can cause pressure fluctuations and chatter.

Diagnosis: Measure hydraulic fluid flow rates and inspect for blockages or restrictions in the system.

Solution: Clean or replace clogged filters and ensure hoses and pumps are appropriately sized for the application.

6. Cavitation

Cause: Cavitation occurs when the hydraulic fluid vaporizes in low-pressure areas, creating bubbles that collapse and cause chattering.

Diagnosis: Listen for a distinctive knocking noise, reduced performance, and inspect for pitted or eroded components.

Solution: Ensure proper fluid levels, maintain appropriate system pressure, and use anti-cavitation measures such as proper pump sizing and fluid selection.

7. Incorrect Cylinder Mounting

Cause: Improper mounting or misalignment of the cylinder can cause uneven loads and chattering.

Diagnosis: Inspect the cylinder mounting for alignment issues, loose bolts, or improper positioning.

Solution: Correct the mounting alignment, tighten bolts, and ensure the cylinder is installed according to specifications.

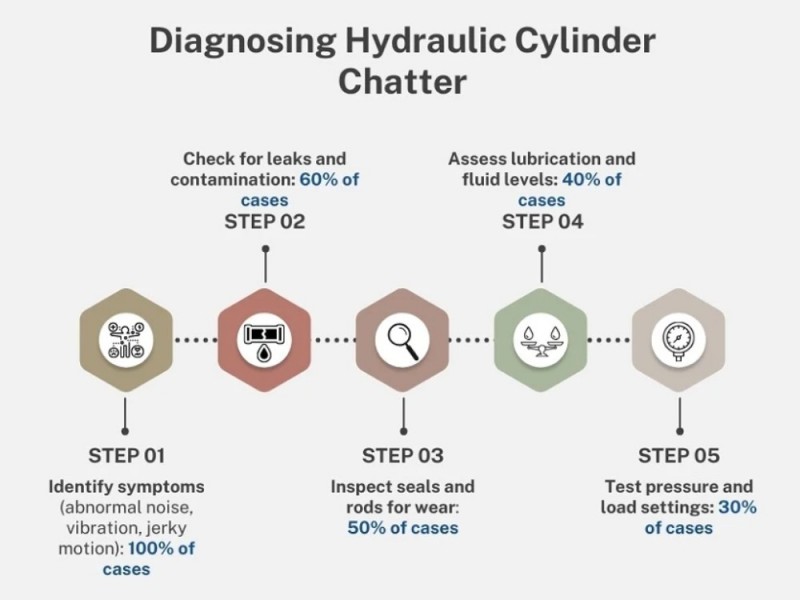

Diagnosing Hydraulic Cylinder Chatter

When to Replace a Hydraulic Cylinder

In some cases, repairing a chattering hydraulic cylinder may not be the most cost-effective solution.

Consider replacing the cylinder if:

-

The damage to the rod, bore, or seals is severe and extensive, leading to repeated equipment failure.

-

The cost of repairs exceeds the value of the hydraulic cylinder or a significant portion of a new cylinder's cost.

-

The hydraulic cylinder has undergone multiple repairs and continues to experience chatter or performance issues, indicating a deeper problem within the hydraulic system.

Conclusion

Hydraulic cylinder chatter can be a frustrating issue, but understanding its causes and implementing proper diagnostic and maintenance practices can help mitigate the problem. Regular inspection, timely maintenance, and using high-quality components and fluids are essential for ensuring the smooth and efficient operation of hydraulic cylinders. By addressing the root causes of chatter, you can enhance the performance and longevity of your hydraulic systems, reducing downtime and increasing productivity.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU