What are phasing cylinders?

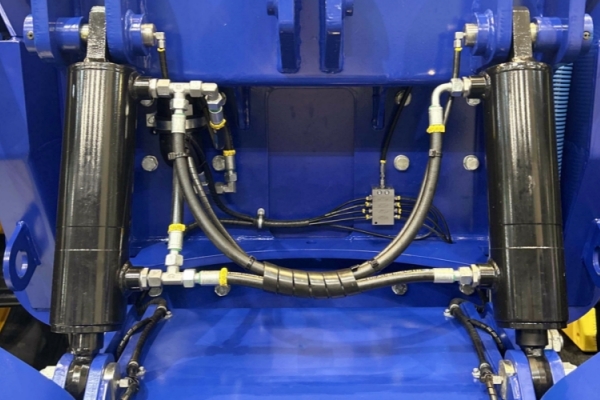

A rephasing hydraulic cylinder system typically consists of two or more hydraulic cylinders connected in parallel, each with its own piston and hydraulic chamber. These cylinders share a common hydraulic fluid source and are interconnected through hydraulic lines or passages.

The key feature of a rephasing system is its ability to ensure that all cylinders extend or retract simultaneously at the same speed. This synchronization is achieved by the strategic placement of valves, check valves, or flow dividers within the system, which regulate the hydraulic fluid flow to maintain uniform movement across all cylinders.A rephasing hydraulic cylinder system typically consists of two or more hydraulic cylinders connected in parallel, each with its own piston and hydraulic chamber.

These cylinders share a common hydraulic fluid source and are interconnected through hydraulic lines or passages. The key feature of a rephasing system is its ability to ensure that all cylinders extend or retract simultaneously at the same speed. This synchronization is achieved by the strategic placement of valves, check valves, or flow dividers within the system, which regulate the hydraulic fluid flow to maintain uniform movement across all cylinders.

What is a rephasing hydraulic cylinder?

Phasing cylinder is essentially a standard hydraulic cylinder with the addition of an important feature - built-in holes or channels that can hydraulically resynchronize the cylinder movement if they are out of synchronisation. Rephasing cylinders are two or more cylinders plumbed in series or parallel, with the bores and rods sized such that all rods will extend and/or retract equally when oil flow is directed to the first, or last, cylinder within the series.

A rephasing hydraulic cylinder is a specialized type of hydraulic cylinder designed to help synchronize the movement of multiple cylinders in a system. These cylinders are often used in applications where several hydraulic cylinders need to extend and retract together at the same speed. The rephasing mechanism allows the cylinders to "phase" or adjust to each other, maintaining uniform movement. This is particularly useful in systems with multi-stage cylinders or where precise control of multiple actuators is necessary.

In a rephasing hydraulic cylinder, a series of internal ports and seals work together to redirect hydraulic fluid between cylinders, enabling them to maintain synchronized motion. When one cylinder moves faster than the others, the rephasing mechanism automatically adjusts the flow of hydraulic fluid to ensure that all cylinders reach the end position at the same time. This ability to "rephase" is crucial for maintaining the efficiency and safety of hydraulic systems, especially in construction machinery, agricultural equipment, and industrial applications.

How to Rephase a Hydraulic Cylinder?

Rephasing a hydraulic cylinder involves ensuring that the hydraulic fluid is properly directed to synchronize the movements of all cylinders in the system.

The first step is to inspect the hydraulic system to ensure that all components, including the rephasing cylinders, are in good condition. Check for any leaks or blockages that may affect fluid flow.

Next, adjust the rephasing valve settings to regulate the flow of hydraulic fluid. These valves control how fluid moves between cylinders, allowing them to stay synchronized. Depending on the type of rephasing cylinder, you may need to adjust the ports or seals to enable proper fluid flow.

Once the valves are adjusted, test the system by operating the cylinders. If the cylinders extend or retract at different rates, the rephasing mechanism should automatically correct the flow to synchronize their movements. It’s important to regularly monitor the hydraulic fluid level and the operation of the rephasing valves to ensure that the system continues to function smoothly and efficiently.

How Does a Rephasing Hydraulic Cylinder Work?

A rephasing hydraulic cylinder works by allowing hydraulic fluid to flow between cylinders in a controlled manner, ensuring that they move in perfect sync. When the cylinder extends or retracts, the internal components adjust the flow of hydraulic fluid to equalize the movement of all connected cylinders. This ensures that all cylinders in a multi-cylinder system reach their end positions at the same time, preventing uneven wear, strain, or damage.

The rephasing mechanism typically consists of a series of check valves and ports that direct hydraulic fluid into the cylinders in a way that allows the slower-moving cylinders to catch up with the faster-moving ones. As the system operates, fluid is shifted from one cylinder to another to balance the movement. In multi-stage cylinders, this ensures that all stages extend and retract together, avoiding any misalignment or discrepancies in the system.

The key benefit of a rephasing hydraulic cylinder is its ability to automatically compensate for differences in cylinder movement. This results in smoother operation, reduces the likelihood of component damage, and ensures that the entire hydraulic system functions efficiently. Rephasing is especially useful in industries such as construction, agriculture, and material handling, where synchronized movement is critical to performance.

Advantages & Disadvantages of Rephasing Hydraulic Cylinders

Phasing Cylinders offer the following advantages:

- Extended Seal Life.

- Robust Design.

- Matching Internal Volumes

- Dual Phasing.

Farmers often use phasing cylinders on the seed rods to control the depth of the seed rods so that all the seeding tines are synchronized at the optimum depth. If the cylinders you tune are not working properly, causing the cylinders to not stay at the correct depth/stroke, they may cut too deep or too shallow. In this way, phasing hydraulic cylinders are also an indispensable part of our lives.

Disadvantages of Rephasing Hydraulic Cylinders

1. Design Complexity: Requires additional components like valves and flow dividers, increasing system complexity.

2. Risk of Leakage: Seals and valves may wear out over time, causing fluid leakage.

3. Application-Specific: Best suited for systems requiring synchronized movement; not ideal for all applications.

4. Fluid Contamination: Contaminated fluid in one cylinder can affect the entire system.

5. Pressure Imbalances: Poor design or maintenance can lead to performance issues that need troubleshooting.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU