Understanding Hydraulic Cylinder Chroming: A Guide for AiSoar Hydraulic Cylinders

Introduction

Chroming is a critical process for enhancing the durability and performance of hydraulic cylinders. By applying a hard chrome layer to the cylinder rod, it significantly increases resistance to corrosion, wear, and friction, ensuring smooth operation under high-pressure conditions. AiSoar cylinders benefit from precise chroming techniques, ensuring superior surface finish and extended service life. This protective coating also reduces maintenance needs and enhances the cylinder's load-handling capacity. Choosing high-quality chroming ensures optimal performance in demanding environments, aligning with AiSoar’s commitment to reliable hydraulic solutions.

What is Chroming?

Chroming refers to the process of electroplating a thin layer of chromium onto a metal surface. This technique is widely used to improve the durability, corrosion resistance, and overall performance of metal components. Chroming involves the following steps:

- Cleaning

The metal surface is thoroughly cleaned to remove any contaminants. - Preparation

The metal is prepared through various mechanical and chemical processes to ensure proper adhesion of the chromium layer. - Electroplating:

The metal part is immersed in a chromium electrolyte solution and subjected to an electric current, causing chromium ions to bond to the metal surface. - Finishing

The chromed surface is polished to achieve a smooth and reflective finish.

Importance of Chroming in Hydraulic Cylinders

Hydraulic cylinders operate under high pressure and are often exposed to harsh environments. Chroming provides several benefits that are crucial for maintaining the performance and longevity of hydraulic cylinders:

Corrosion Resistance

Chroming creates a protective layer that prevents the metal surface from rusting, even in corrosive environments.

Wear Resistance

The hard chromium layer significantly reduces wear and tear, extending the life of the hydraulic cylinder.

Low Friction

A chromed surface offers low friction, which improves the efficiency of the hydraulic cylinder by reducing energy loss during operation.

Enhanced Strength

The chromium layer enhances the mechanical strength of the metal, making it more resistant to impacts and deformation.

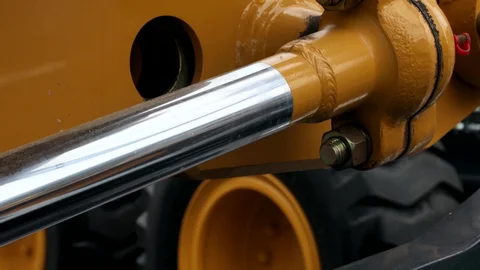

Chroming the Hydraulic Rod

The hydraulic rod, also known as the piston rod, is a critical component of a hydraulic cylinder. It connects the hydraulic piston to the machinery it operates and transfers the hydraulic force to perform work. Given its crucial role, the hydraulic rod requires exceptional durability and resistance to environmental factors. Chroming is particularly beneficial for the hydraulic rod for the following reasons:

Improved Durability

The hydraulic rod is constantly exposed to friction and high-pressure conditions. Chroming enhances its wear resistance, ensuring long-term performance.

Corrosion Protection:

The hydraulic rod is often exposed to moisture and other corrosive elements. Chroming provides a protective barrier that prevents rust and corrosion.

Smooth Operation:

A chromed hydraulic rod has a smooth surface that reduces friction, leading to more efficient and precise movement within the cylinder.

Aesthetic Appeal

The shiny, polished finish of a chromed rod not only looks professional but also indicates a high-quality component.

Hydraulic Cylinder Chrome Plating Flow Process

Chrome plating is a critical process in the manufacturing of hydraulic cylinders, particularly for enhancing the performance and durability of the hydraulic rod. At AiSoar, we follow a meticulous chrome plating process to ensure the highest quality and reliability of our products. Below is a detailed flow process of hydraulic cylinder chrome plating:

Step1:Pre-Cleaning

Objective: Remove dirt, grease, and other contaminants from the hydraulic rod.

- Degreasing: The hydraulic rod is cleaned using solvents or alkaline solutions to remove oils and grease.

- Rinsing: The rod is thoroughly rinsed with water to remove any residual cleaning agents.

Step2:Surface Preparation

Objective: Prepare the hydraulic rod surface to ensure proper adhesion of the chrome layer.

- Mechanical Polishing: The rod is mechanically polished to remove any surface imperfections and to create a smooth finish.

- Abrasive Blasting: Abrasive blasting is performed to create a slightly rough surface, which helps the chromium adhere better.

- Acid Etching: The rod is treated with an acid solution to further clean and roughen the surface at a microscopic level.

Step3:Chrome Plating

Objective: Electroplate a layer of chromium onto the hydraulic rod.

- Immersion: The rod is immersed in a chromium electrolyte solution within the plating tank.

- Electroplating: An electric current is applied, causing chromium ions to deposit onto the rod's surface. The duration and current density are carefully controlled to achieve the desired thickness and uniformity of the chrome layer.

- Monitoring: Throughout the process, the plating conditions are continuously monitored to ensure consistent quality.

Step4:Post-Plating Rinse

Objective: Remove any residual plating solution from the rod.

- Rinsing: The rod is rinsed with water to remove any remaining electrolyte solution.

- Neutralizing: The rod is immersed in a neutralizing solution to remove any acidic residues.

Steps5: Post-Plating Rinse

Rinsing: The rod is rinsed with water to remove any remaining electrolyte solution.

Neutralizing: The rod is immersed in a neutralizing solution to remove any acidic residues.

Conclusion

Chroming is an essential process in the manufacturing of AiSoar hydraulic cylinders, particularly for the hydraulic rod. By electroplating a layer of chromium onto the metal surface, we enhance the durability, corrosion resistance, and overall performance of our hydraulic cylinders. This ensures that our products meet the highest standards of quality and reliability, capable of withstanding the most demanding applications.

For more information about our chroming process and its benefits for hydraulic cylinders, please visit our website or contact our technical support team. At AiSoar, we are committed to delivering excellence through advanced manufacturing techniques and superior materials.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU