Top Hydraulic System Problems and How to Fix Them Effectively

What Are the Common Problems in Hydraulic Systems?

Facing Hydraulic Issues? Here's the Solution.

Slow hydraulics, loud noises, and trapped air can stop your system in its tracks, causing costly downtime and inefficiency. A thorough understanding and timely fixes can restore performance and minimize long-term damage.

Slow operation, loud noises, and air in hydraulic systems are frequent issues caused by contamination, wear, or poor maintenance. Addressing these problems promptly can extend equipment life and prevent downtime.

What Causes Hydraulics to Run Slow?

A slow hydraulic system is often a result of low fluid levels, clogged filters, worn-out components, or incorrect viscosity of hydraulic oil. Inadequate fluid flow restricts power delivery to actuators, leading to a slow bucket or sluggish system response. Another cause is improper calibration of hydraulic pumps and valves, which can affect pressure and flow. Regular inspection of fluid levels, filters, and system calibration is critical to prevent these issues.

How to Control the Speed of a Hydraulic System?

To control the speed of a hydraulic system, use flow control valves or variable displacement pumps. Flow control valves regulate the amount of hydraulic fluid reaching the actuators, ensuring smooth and precise movement. Alternatively, variable displacement pumps adjust the amount of fluid delivered by the pump to meet system demands. A hydraulic mechanism that slows or restricts movement, such as restrictors or orifices, can also be employed for precise adjustments. Regular maintenance of these components is essential for optimal performance.

Why Do I Hear Loud Noises from My Hydraulic System?

Loud noises in a hydraulic system often result from cavitation or aeration. Cavitation occurs when the system’s fluid contains vapor bubbles, typically due to low fluid levels or high suction pressure. Aeration happens when air enters the system, usually through loose fittings or worn seals. Both problems lead to noisy operation and can damage pumps and other components over time. To fix this, ensure proper fluid levels, tighten connections, and replace damaged seals.

What Problems Are Caused by Trapped Air in a Hydraulic System?

Trapped air in a hydraulic system reduces efficiency and can lead to erratic or jerky movements. The presence of air compresses under pressure, causing a delay in actuator response, which can slow the bucket or other hydraulic components. Over time, this leads to increased wear and tear on the system, including cavitation damage and contamination. Preventing air in the hydraulic system is essential to ensure smooth operation and system longevity.

Traditional Efforts to Deal with Trapped Air: Hand Bleeding and Drilled Hole Method

To remove trapped air, the most common methods include hand bleeding and the drilled hole method. Hand bleeding involves manually opening bleed valves to release air pockets from the system. The drilled hole method, though less common, involves drilling a small hole at strategic points in the system to allow air to escape. Both methods require care to avoid introducing contaminants or causing damage. While these approaches can help in the short term, advanced hydraulic systems now include automatic air purging mechanisms to simplify the process.

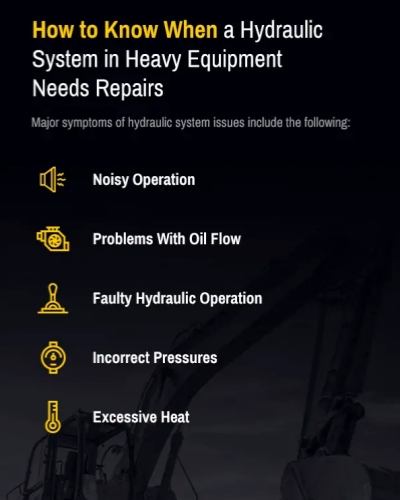

How Do I Know If My Hydraulic System Is Having Problems?

How Do I Know If My Hydraulic System Is Having Problems?

You can identify hydraulic issues through performance changes, unusual noises, and visual inspections. Look for symptoms such as a slow bucket, erratic movement, or low system pressure. Check for leaks, discolored or contaminated hydraulic fluid, and excessive heat generation. Monitoring system performance regularly and addressing abnormalities promptly can help prevent major breakdowns.

Preventing Hydraulic Problems Saves Time and Money.

Routine inspections, proper maintenance, and early problem detection ensure your hydraulic system operates efficiently and avoids costly downtime.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU