The Ultimate Guide to Hydraulic Cylinder Parts: Functions, Maintenance, and Common Issues

Are you familiar with the essential components of a hydraulic cylinder? A hydraulic cylinder is composed of several key parts, including the barrel, piston, rod, seals, and end caps. Understanding these components is critical to ensuring the smooth operation and longevity of the hydraulic system. In this guide, we’ll explain the functions of each part and provide tips for maintaining them. Keep reading to learn more.

Hydraulic cylinders are crucial for many heavy-duty applications, and their parts play a significant role in performance and longevity. In this guide, we’ll break down the key components of a hydraulic cylinder and provide maintenance tips to keep your system running smoothly.

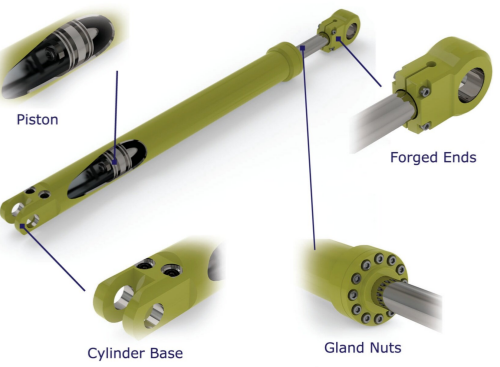

Understanding the Essential Parts of a Hydraulic Cylinder

A hydraulic cylinder is made up of several key components that work together to convert hydraulic energy into mechanical force. The main parts include the cylinder barrel, piston, rod, seals, and end caps. Each part serves a specific purpose in ensuring the smooth operation of the hydraulic system. For example, the cylinder barrel houses the piston and rod, while the piston helps in generating the force. The seals prevent leaks, and the end caps provide structural integrity. A well-designed hydraulic cylinder ensures optimal performance and efficiency.

The Role of Seals in Hydraulic Cylinders: Protecting Performance and Efficiency

Seals are crucial components in hydraulic cylinders, responsible for preventing fluid leakage and protecting the internal parts from contaminants. Without proper sealing, hydraulic fluid could leak, reducing efficiency and causing severe damage to the cylinder. Seals must be regularly inspected and replaced to avoid potential malfunctions. In addition to preventing leaks, seals protect the hydraulic system from dirt, dust, and other harmful particles that can cause wear and tear. Choosing the right seals for your hydraulic cylinder is key to ensuring long-term performance.

Seals are crucial components in hydraulic cylinders, responsible for preventing fluid leakage and protecting the internal parts from contaminants. Without proper sealing, hydraulic fluid could leak, reducing efficiency and causing severe damage to the cylinder. Seals must be regularly inspected and replaced to avoid potential malfunctions. In addition to preventing leaks, seals protect the hydraulic system from dirt, dust, and other harmful particles that can cause wear and tear. Choosing the right seals for your hydraulic cylinder is key to ensuring long-term performance.

How Hydraulic Cylinder Rods Affect Performance and Durability

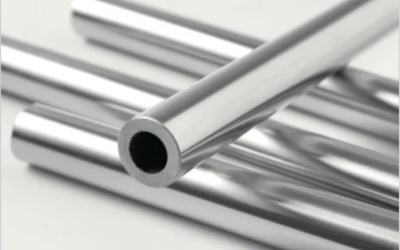

The hydraulic cylinder rod is a central component that transmits force from the piston to the external mechanism. Made from high-strength materials, the rod is designed to withstand significant stress and pressure. If the rod is damaged or wears out, it can lead to decreased performance and efficiency, causing the cylinder to malfunction. Rods must be smooth and free of defects to ensure smooth operation and prevent unnecessary friction. Regular inspection of the rod’s surface is essential to avoid performance issues. Ensuring the rod is properly coated or treated can further enhance its durability.

The hydraulic cylinder rod is a central component that transmits force from the piston to the external mechanism. Made from high-strength materials, the rod is designed to withstand significant stress and pressure. If the rod is damaged or wears out, it can lead to decreased performance and efficiency, causing the cylinder to malfunction. Rods must be smooth and free of defects to ensure smooth operation and prevent unnecessary friction. Regular inspection of the rod’s surface is essential to avoid performance issues. Ensuring the rod is properly coated or treated can further enhance its durability.

What is the Hydraulic Piston? Functions and Types Explained

The hydraulic piston is one of the most critical parts of a hydraulic cylinder. It plays a key role in converting the pressure from hydraulic fluid into mechanical force, making it essential for the cylinder's operation. There are different types of pistons, including single-piece pistons and modular pistons, which are designed based on the application. Each piston type offers distinct advantages, such as increased force, better load-bearing capacity, and improved durability. Understanding the type of piston in your hydraulic cylinder can help you optimize the system for specific applications.

Cylinder Barrel Materials: What You Need to Know for Optimal Durability

The cylinder barrel is the housing that contains the piston and rod assembly. Its material plays a vital role in the overall durability and efficiency of the hydraulic cylinder. Common materials used for cylinder barrels include steel and high-strength alloys. These materials are chosen for their resistance to corrosion, wear, and pressure. Choosing the right material based on the working environment and load conditions is crucial. A well-maintained barrel not only ensures efficient operation but also prevents issues like pitting, corrosion, and premature wear.

Hydraulic Cylinder End Caps: Their Importance in Sealing and Functionality

End caps play a vital role in sealing the ends of the hydraulic cylinder and ensuring the internal components remain secure. They are designed to prevent fluid leakage and protect the cylinder from external contaminants. Additionally, end caps help in securing the piston and rod within the barrel. These components must be carefully chosen to ensure compatibility with other parts, as any mismatch can lead to leakage or failure. High-quality end caps are essential for maintaining the integrity of the hydraulic cylinder and extending its lifespan.

Choosing the Right Hydraulic Cylinder Parts for Your Application

When selecting hydraulic cylinder parts, it’s important to consider factors like the application, operating conditions, and load requirements. For example, if the cylinder will be exposed to extreme temperatures, materials with high-temperature resistance should be chosen. Similarly, the piston and rod must be selected based on the force requirements of the application. Using high-quality, compatible parts ensures better performance, longer service life, and fewer maintenance issues. Consulting with hydraulic cylinder experts can help you make the right choices for your specific needs.

Common Hydraulic Cylinder Parts Failures and How to Avoid Them

Hydraulic cylinders can experience various failures due to improper maintenance or incorrect usage of parts. Common issues include seal damage, rod wear, and piston failure. Regular inspections are key to identifying potential problems early and preventing costly repairs. Keeping hydraulic fluid clean and maintaining proper pressure levels can prevent seal degradation, while protecting the rod from scratches and corrosion can reduce wear. By staying proactive with maintenance, you can significantly reduce the likelihood of failure and ensure the longevity of your hydraulic system.

Conclusion

Hydraulic cylinder parts are essential for the efficiency and longevity of your machinery. Regular maintenance and proper component selection can help avoid costly failures and ensure optimal performance.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU