The Reason Why Hydraulic Cylinder Won’t Retract

ARTICLE CONTENT

1. Article Introduction

2. How Does Hydraulic Cylinders Retract?

3. Troubleshooting Guide for Hydraulic Cylinder Retraction Issues

4. How to Prevent Retraction Issues in Hydraulic Cylinders?

5. Conclusion

A hydraulic cylinder that won't retract can halt operations, leading to costly downtime and possible damage to your equipment. Here's how to address this issue effectively.

Hydraulic cylinders may not retract due to low pressure, internal leaks, contamination, or physical damage. Issues like worn seals, clogged valves, or bent rods can block the cylinder’s movement. Regular maintenance and inspection are essential to prevent these problems and ensure smooth operation.

All processes stop when the hydraulic cylinders fail to retract. From the perspective of maintenance and the downtime incurred in troubleshooting the problem, the situation is aggravating. It can be helpful to know what typical issues retracting hydraulic cylinders face and to take preventative measures to avoid them entirely.

How Does Hydraulic Cylinders Retract?

Hydraulic cylinders operate on a straightforward principle: fluid power. When pressurized hydraulic fluid is pumped into one end of the cylinder, it pushes the piston to extend or retract based on fluid direction. The fluid enters one chamber of the cylinder, creating force that moves the piston rod. When the fluid is directed to the opposite chamber, it retracts the piston rod, drawing it back into the cylinder.

The Reasons Why Your Hydraulic Cylinder Won’t Retract

1. LOW HYDRAULIC PRESSURE

If there isn’t enough hydraulic pressure, the cylinder may lack the force to retract. This often results from a weak pump, clogged filters, or low fluid levels.

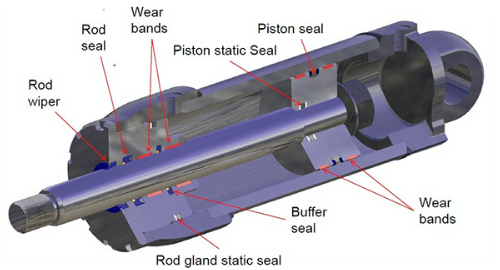

2. DAMAGED OR WORN PISTON SEALS

Although seals naturally deteriorate with time, fluid leaks occur when they are not replaced. Cylinders that are hydraulically locked—that is, unable to retract or extend completely—occur when there is not enough hydraulic fluid in your system. Hydraulic cylinders may have difficulties retracting if worn seals result in misalignment between the seal and cylinder rod.

3. HYDRAULIC FLUID CONTAMINATION

Hydraulic fluid is crucial for smooth hydraulic operations, ensuring cylinder lubrication, facilitating heat dissipation, and transferring power. However, contaminated hydraulic fluid can cause equipment damage. Foreign particles can act as abrasives, harming vital internal components or causing obstructions in the fluid flow.

4. A BENT OR DENTED BARREL OR CYLINDER ROD

Dents in barrels or rods can occur from impacts or by lifting loads beyond the cylinder’s capacity. If the rod or barrel is deformed, the cylinder may be unable to retract properly due to restricted movement.

5. FAULTY CONTROL VALVES

Control valves regulate the flow and direction of hydraulic fluid. A stuck or malfunctioning valve can block the flow, making it impossible for the cylinder to retract. This issue may require recalibration or replacement of the valve.

6. RETRACTING HYDRAULIC CYLINDERS UNDER LOAD

Hydraulic drift is when cylinders retract unintentionally, often due to internal fluid leaks. Under heavy loads, this delayed retraction can damage equipment or pose safety risks, even though it’s less hazardous in light-duty settings.

7. EXTREME TEMPERATURES

Hydraulic cylinders work best within specific temperature ranges. Excessive heat accelerates seal wear and breaks down hydraulic fluid, causing leaks and erratic performance. Extreme cold thickens fluid, reducing lubrication and hindering movement.

8. WRONG INSTALLATION

Improper cylinder installation can lead to mechanical problems, including misalignment, accelerated wear, and even system failure. These issues stress the hydraulic system, impairing the cylinder's ability to extend and retract effectively.

Troubleshooting Guide for Hydraulic Cylinder Retraction Issues

Visual Inspection of Hydraulic Hoses

- Look for Visible Cracks or Abrasions: Examine the entire length of each hose, looking for any signs of cracks, cuts, or abrasion on the surface. Over time, hoses can degrade or wear down due to friction, environmental exposure, or movement during operation.

- Check for Swelling or Bulges: Swollen or bulging hoses can indicate internal damage or weaknesses caused by excessive pressure. If you see bulges, it’s a sign that the hose may need to be replaced.

- Inspect Hose Fittings and Clamps: Ensure that the fittings and clamps securing the hoses are in place and not loose. Loose fittings can cause leaks or allow hoses to move, leading to wear and eventual failure.

- Look for Signs of Oil Residue: Hydraulic fluid leakage will often leave a visible oil residue on or around the hose. If you see oil on a hose surface, especially near the fittings, it may indicate a leak.

Inspect Seals for Leaks and Wear

- Focus on Cylinder Seals: The seals around the cylinder rod are prone to wear and are a common source of hydraulic leaks. Check the rod seal area, which is where the rod exits the cylinder, for any signs of oil leakage.

- Look for Oil Residue Around Seal Areas: Even a small leak will leave traces of oil around the seals. Look closely at the areas around the seals for any signs of wetness, oil film, or build-up of dirt and dust sticking to oil residue.

- Inspect for Cracks, Breaks, or Fraying: Seals can become brittle over time, leading to cracks or breaks that cause leaks. Inspect all visible seals for signs of cracking, fraying, or other wear.

- Move the Rod In and Out: If possible, extend and retract the cylinder rod manually (if safe) to check if the seals leak under movement. Sometimes, leaks only become visible when the cylinder is in motion.

Check for Bending or Warping

- Roll Test: Place the rod on a flat surface and roll it. If it doesn’t roll smoothly, it may be bent or warped, which can cause the cylinder to stick or fail to retract.

- Straight Edge or Dial Indicator: For a more precise check, place a straight edge along the length of the rod or use a dial indicator. Any deviation from straightness suggests the rod may need replacement.

Check for Corrosion or Rust

- Chrome Coating: Hydraulic rods are often chrome-plated to prevent corrosion. Look for any rust or corrosion spots, as this means the protective coating has been compromised, leading to further wear and potential leaks.

Inspect the Rod’s Finish and Coating

- Surface Condition: The rod’s surface should be smooth and polished to prevent abrasion of the seals. If the chrome plating is peeling, flaking, or worn down, the rod likely needs repair or replacement.

Check Alignment Between the Cylinder and Connected Components

- Use a Straight Edge or Laser along the rod to check precise alignment with connected components.

- Ensure Mounting Points Are Parallel and pivot points are aligned to avoid twisting or binding. Adjust as needed to align the rod’s centerline with the load.

How to Prevent Retraction Issues in Hydraulic Cylinders

Preventing retraction issues with hydraulic cylinders involves regular maintenance and proactive care:

Routine Inspections: Regularly inspect cylinders, rods, seals, and hydraulic fluid for any signs of wear or contamination. Early detection of issues can prevent breakdowns.

Hydraulic Fluid Management: Ensure that hydraulic fluid is clean and at the correct level. Use high-quality filters to remove contaminants and regularly replace or clean filters as recommended.

Seal and Component Replacement: Replace seals, control valves, and other critical components as needed. Waiting until these parts completely fail can result in more costly repairs or equipment downtime.

Proper Storage and Handling: Store hydraulic cylinders in a clean, dry environment to prevent rust and contamination. Handle components carefully to avoid bending or damaging rods.

Conclusion

In summary, hydraulic cylinders may fail to retract due to pressure issues, leaks, contamination, or physical damage. Regular maintenance and prompt repairs are essential to prevent these issues, ensuring reliable and efficient cylinder operation.If you meet any issue about hydraulic cylinder ,please contact pressional personnel.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU