Most Common Causes of Hydraulic Cylinder Failure

Hydraulic cylinders are mechanical actuators that provide functionality and directional force. They have numerous applications, from engineering vehicles to civil engineering and manufacturing equipment. Regular inspections and maintenance of hydraulic cylinders are necessary for cylinders to function effectively and efficiently.

Though they generally last for years, even with inspections, there are many hydraulic cylinder problems that can cause failure. Below are the most common hydraulic cylinder failure causes that must be addressed in order to maintain effective hydraulic systems.

Seal Failure

Seals are the most easily damaged component of a cylinder. They are the weakest part of the cylinder and can fail for many reasons including scratched piston rods, break down from the heat, contaminated fluid, or pressure spikes.

Abrasives, incorrect fitting, and chemical erosion can also cause hydraulic cylinder piston seal failure and seal leakage. Seals that have been damaged by any of these occurrences and experience leakage can ruin the cylinder’s ability to maintain a certain pressure.

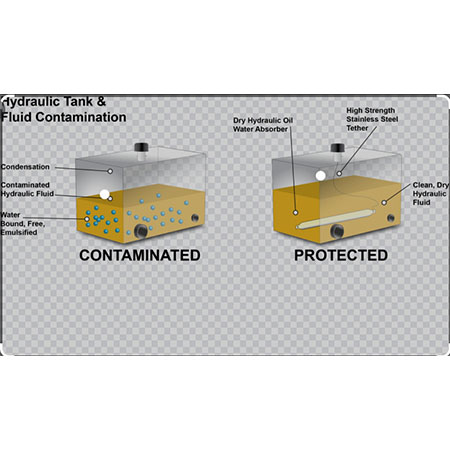

Fluid Contamination

One of the most common reasons for hydraulic cylinder failure is contaminated fluid. When foreign, abrasive particles become trapped in the fluid they scratch the inside of the cylinder, ruin the finish of cylinder rods, block ports, and damage seals and fittings. Though hydraulic fluid does degrade with time, faulty wiper seals are generally the cause of accelerated fluid contamination.

Extreme Temperatures

Extreme temperatures affect the function of hydraulic cylinders:

- In extreme heat, polyurethane seals will lose their effectiveness and their shape. In the cold, the seals will become brittle, losing their elasticity.

- Either extreme temperature will damage the fluid in the hydraulic cylinders. The harsh conditions will affect the viscosity of the hydraulic fluid and lead to leakage and system failure

Hydraulic Cylinder Side Loads

Hydraulic cylinders are designed to apply linear force along an axis that is aligned with the cylinder. When cylinders are installed improperly, the force is applied perpendicular to the intended direction and side loading occurs. Sideloading causes uneven wearing because the rod pushes and the piston drags with more force on one side than the other.

Moderate sideloading will accelerate the degradation of the cylinder and the cylinder will need to be repaired sooner. However, excessive side loading and uneven wear to various components will have more catastrophic results, as it leads to failure of the system and a potentially dangerous situation.

Piston damage

There are a few causes for piston damage; it is possible the nut or piston retaining device will become looser over time and pistons will often wear out with time like any mechanical equipment. Also, side loading or contaminated fluid could cause damage to the pistons. Ultimately, the piston damage will cause complete cylinder failure and the device will lose power.

Incorrect pressure

In order to perform effectively, it is essential to monitor and maintain precise and controlled internal hydraulic pressure. When there are pressure variations within the system that are not according to the manufacturer’s specifications it could lead to potentially dangerous conditions. Regular checks and adjustments should be made to comply with the system’s specifications.

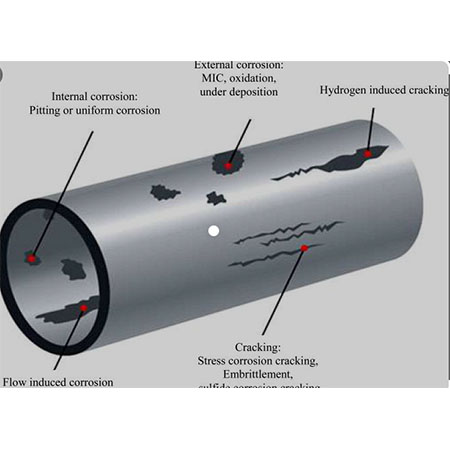

Corrosion

Another common problem with hydraulic cylinders is corrosion; corrosion appears as rust and pitting on the rods and stages of the cylinder. Equipment is sometimes stored outdoors, with the cylinders extended, exposing the rods to the elements.

Over time, specks of rust will form and then develop into pits and as soon as the cylinder is retracted, the rod will destroy the seal of the cylinder. This problem can be eliminated by regularly using the cylinder so a micro oil film can form on the cylinder rod.

Cylinder Bore Scoring

Cylinder bore scoring presents as deep gouges or harsh scuffs to the interior of the bore walls. This will be most noticeable where the piston is in its fully extended position at the mouth of the barrel. In the fully extended position, there is less support which results in increased friction and forces. Cylinder bore scoring might occur if cylinders are not mounted properly or cannot accommodate for alignment changes. Increased side-load forces, which lead to a crooked rod, can also cause cylinder bore scoring. Scoring is most often found in long-stroke cylinders.

Conclusion

Hydraulic cylinders can fail for a number of reasons, from seal failure to pressure and temperature issues, and understanding why the cylinders can fail will reduce the chances it occurs. Regular checks are an essential part of ensuring the overall system is working safely and effectively.

However, if maintenance or repairs are necessary, Aisoar can help you fix our cylinders quickly and affordably. If you notice problems with your hydraulic cylinders, talk to our experts to find out more and schedule your repairs.

Aisoar Hydraulics has the knowledge and experience needed to service your hydraulic cylinders.

Hangzhou Aisoar hydraulic technology Co.,Ltd

Tel: 86-571-87920309

Fax: 86-571-87926329

Mob&Wechat&Whatsapp: +86 13588456446

Email:Jack@ai-soar.com

ES

ES RU

RU