What is Mini Excavators Hydraulic Cylinders?

Excavators rely on hydraulic cylinders for efficient movement and function, but choosing the right type is critical. If the wrong cylinder is used, it can result in performance issues, costly repairs, and downtime. Understanding the types and functions of hydraulic cylinders used in excavators can save time and money. Keep reading to learn more.

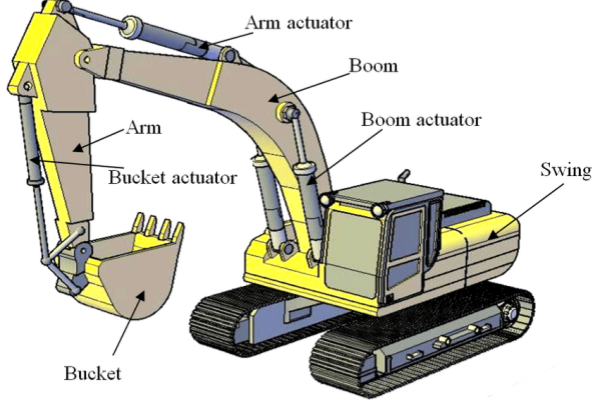

Hydraulic cylinders play a vital role in the functioning of excavators, with different types suited for specific functions. These include the boom, arm, and bucket cylinders. Understanding these parts is key to optimizing performance and avoiding costly repairs.

To dive deeper into how these cylinders function, let’s explore the specific types of hydraulic cylinders in excavators and their common issues.

How Many Hydraulic Cylinders Does an Excavator Have?

Excavators typically have four main hydraulic cylinders: one for the boom, one for the arm, one for the bucket, and one for the swing. Each cylinder is responsible for controlling a specific part of the excavator's movement. The boom lift cylinder, for example, raises and lowers the boom, which is the large arm of the excavator. The arm and bucket cylinders are responsible for the movement of the arm and bucket, respectively. Additionally, some excavators may also have auxiliary cylinders for specific attachments or functions.

1. Bucket Cylinder

The bucket cylinder is responsible for providing the power required to move the bucket, which is located at the end of the bucket arm. This hydraulic cylinder is typically smaller in size compared to other cylinders, but it is crucial for controlling the angle of the bucket during excavation.

2. Boom Cylinder

The boom cylinder is one of the largest and most powerful hydraulic cylinders on a mini excavator. It is used to raise and lower the main boom, which is the large arm that connects the machine’s undercarriage to the attachment. This cylinder generates a large amount of force to lift and position the boom, which is essential for reaching higher or deeper excavation sites.

3. Stick Cylinder (Dipper Cylinder)

The stick cylinder, also known as the dipper cylinder, powers the movement of the stick arm, which carries the bucket. The stick arm, or dipper, is the intermediate link between the boom and the bucket. The cylinder extends and retracts to control the depth and reach of the bucket during excavation.

4. Swing Cylinder

The swing cylinder, also known as the rotary cylinder, controls the rotation of the upper part of the excavator around its vertical axis. This rotation allows the operator to change the direction of the boom and bucket, which is crucial for precise operation in tight spaces or for digging in multiple directions.

5. Dozer Cylinder (Blade Cylinder)

The dozer cylinder is responsible for controlling the movement of the dozer blade, a key component at the front of the mini excavator. This blade is used for pushing materials such as dirt, sand, or gravel. The dozer cylinder also helps stabilize the excavator during operation, especially when working on uneven surfaces.

What's the Difference of Hydraulic Cylinders on Excavators?

The hydraulic cylinders on excavators differ in size, strength, and function depending on the task they are designed for. For example, the boom lift cylinder (also known as the hydraulic boom cylinder) is designed to support the weight of the entire boom and to move it vertically. On the other hand, the arm and bucket cylinders are smaller and designed for more precise movements. The key difference lies in their size and force output – the boom lift cylinder is the largest and strongest, while the bucket cylinder is smaller and more focused on detailed control.

| Hydraulic Cylinder | Function | Location | Purpose |

| Bucket Cylinder | Controls the movement and tilt of the bucket. | Mounted on the bucket arm. | Moves the bucket for digging and scooping. |

| Boom Cylinder | Raises and lowers the main boom. | Attached to the base of the boom. | Provides vertical movement and power for lifting. |

| Stick Cylinder | Powers the movement of the stick arm. | Mounted on the stick arm. | Controls the reach and depth of the bucket. |

| Swing Cylinder | Rotates the upper part of the excavator. | Attached to the upper frame. | Allows 360-degree rotation for multi-directional movement. |

| Dozer Cylinder | Controls the lifting and lowering of the dozer blade. | Attached to the dozer blade. | Assists in pushing materials and stabilizing the excavator. |

What is a Boom Lift Cylinder?

The boom lift cylinder, often referred to as the hydraulic boom cylinder on an excavator, is the most important hydraulic cylinder when it comes to raising and lowering the boom. The boom itself is the long, heavy arm that provides the excavator with reach and height. This hydraulic cylinder is designed to handle heavy loads and apply the necessary force to lift the boom into various positions. The boom lift cylinder is typically located at the base of the boom and is essential for the excavator’s overall function.

Conclusion

Hydraulic cylinders are integral to the operation of excavators, each serving a distinct function to ensure the machine performs optimally. Understanding the types of cylinders used, their roles, and potential issues is key to maintaining the machine's efficiency and longevity. With proper maintenance and attention, you can ensure your excavator operates without unnecessary downtime.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU