Mastering Hydraulic Spool Valve Adjustment for Optimal Cylinder Performance

Spool valves play a pivotal role in controlling the direction, pressure, and flow of hydraulic fluid, which in turn affects the motion and force output of the hydraulic cylinder. As a leading manufacturer of hydraulic cylinders, AiSoar is here to guide you through the intricacies of hydraulic spool valve adjustment.

What is a Hydraulic Spool Valve?

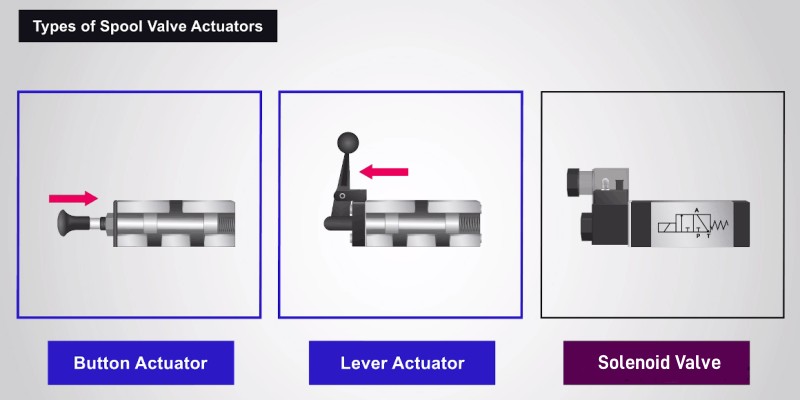

Before we dive into adjustments, let's first understand what a spool valve is. A hydraulic spool valve is a key component used in hydraulic systems to control the start, stop, and direction of fluid flow. It operates by moving a cylindrical spool within a housing, thus opening and closing paths for hydraulic fluid to flow. The precise positioning of the spool determines the behavior of the hydraulic cylinder.

The Importance of Correct Valve Adjustment

Proper adjustment of the spool valve is critical for several reasons. First and foremost, it ensures that the hydraulic system operates efficiently, providing the right amount of force and speed as needed. Correct adjustment also prevents potential damage to the system by avoiding excessive pressure and flow that could strain the hydraulic cylinder and other components.

Step-by-Step Guide to Adjusting Hydraulic Spool Valves

Step 1: Understand Your Valve Configuration

Familiarize yourself with the specific type of spool valve in your system, including its configuration and the manufacturer’s adjustment guidelines. Different systems might require different adjustment approaches.

Step 2: Safely Depressurize the System

Before making any adjustments, ensure the hydraulic system is safely depressurized. This prevents any accidental discharge of hydraulic fluid or unexpected movement of the hydraulic cylinder, ensuring a safe environment for maintenance or adjustment.

Step 3: Locate the Adjustment Mechanism

Identify the adjustment screw or knob on the spool valve. This mechanism typically allows you to control the flow rate or pressure limit within the hydraulic system. Some valves also feature an electrical or manual override function that can be useful for testing and adjustments.

Step 4: Adjust the Spool Valve

Using appropriate tools, gently turn the adjustment mechanism. Depending on your system's needs, you may need to either increase or decrease the pressure, flow rate, or change the valve's opening and closing timing. Always refer to the manufacturer's specifications to determine the correct settings.

Step 5: Test the Adjustment

After making adjustments, it’s crucial to test the hydraulic system to ensure the spool valve is operating correctly. Observe the response of the hydraulic cylinder and make additional adjustments as necessary.

Step 6: Monitor System Performance

After the system is back in operation, continue to monitor its performance closely. Look for any signs of erratic operation or inefficiency, which could indicate further adjustments are needed.

Conclusion

Adjusting a hydraulic spool valve is a critical skill for anyone involved in the maintenance or operation of hydraulic systems. Proper adjustment ensures optimal performance, efficiency, and longevity of both the valve and the hydraulic cylinder it controls. At AiSoar, we understand the importance of precision in hydraulic systems and are committed to providing high-quality components and expertise to support your operational needs.

Should you have any further questions about adjusting hydraulic spool valves or need assistance with your hydraulic cylinders, don’t hesitate to reach out to our team of experts. We're here to help you achieve seamless and efficient hydraulic operations.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales @ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU