What are Mounting Type of Hydraulic Cylinders?

ARTICLE CONTENT

1. Article Introduction

2. Overview of Common Cylinder Mounting Type

3. Characteristics of Different Mount Type

4. Understanding Pivot Mounts: Clevis, Trunnion, and Spherical Bearings

5. Key Factors to Consider When Choosing a Hydraulic Cylinder Mount Type

6. Installation Tips for Hydraulic Cylinder Mounting

7.Summary

Hydraulic cylinders require proper installation to function effectively. Poor mounting can lead to misalignment, excessive wear, and even system failure. Choosing the right mounting method helps avoid these issues, ensuring smooth operation and long-lasting performance.

Hydraulic cylinders can be mounted using foot mounts, flange mounts, and pivot mounts (such as clevis, trunnion, and spherical bearings). Each mounting type serves different applications and movement requirements.

Curious about the best installation method for your hydraulic cylinder? Read on to find the ideal mounting type for your needs.

Overview of Common Cylinder Mounting Type

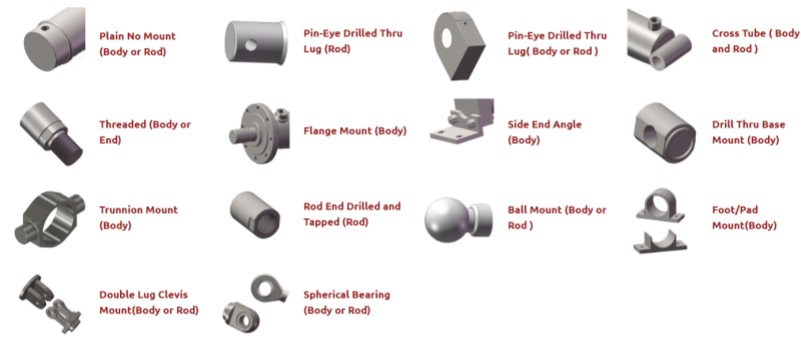

Foot Mounts (Side Lug, End Lug, and Centerline Foot): It is applicable to the fixed installation of the hydraulic cylinder during the working process, and its installation plane is not in the same plane as the cylinder central axis . When selecting this kind of installation, the installed structure must be well positioned and fastened. The installation methods include end and side lug installation.

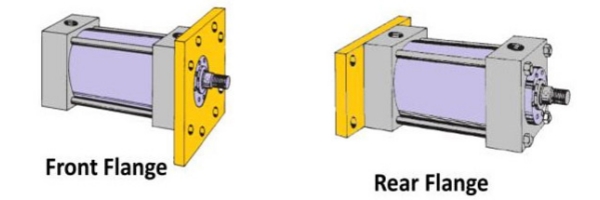

Flange mounting—Flanges are the parts that connect pipes together. Bolts can pass through the holes in the flange. There are various types of flanges, including rectangular flanges, square flanges, round flanges, and others. Flange mounting is suitable for transmitting linear force and has the advantage of being very strong.

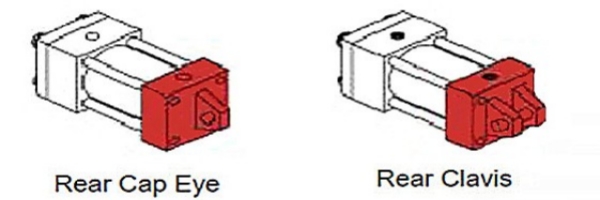

Pivot Mounts (Clevis, Trunnion, and Spherical Bearing Mounts): Ideal for applications where the cylinder needs to pivot, allowing for angular movement.

Swivel Ball End Mounted Hydraulic Cylinders: Connect the swivel ball end of the hydraulic cylinder with the ball seat on the machine so that the hydraulic cylinder can swing freely within a certain space.

Characteristics of Different Mount Type

Hydraulic cylinders come with various mounting options, each designed for a specific range of applications, loads, and movement requirements. The most common types include:

| Mount Type | Characteristics | Application |

| Foot Mounts | Provide a stable, fixed base for stationary applications. | Industrial Presse,Conveyor Systems |

| Flange Mounts | Compact and strong, often used in space-constrained environments | Press Machines,Hydraulic Press Brakes,Robotic Arms |

| Clevis Mounts: | Flexibility and angular movement, ideal for dynamic or mobile applications | excavators and agricultural machinery. |

| Trunnion Mounts | Cranes or other machinery requiring extensive movement | |

| Spherical Bearings | Mining equipment or construction machinery. |

Understanding Pivot Mounts: Clevis, Trunnion, and Spherical Bearings

Pivot mounts, including clevis, trunnion, and spherical bearing mounts, allow cylinders to move in an arc, making them ideal for applications with angular movement. Clevis mounts are commonly used in mobile equipment and allow for limited rotational movement. Trunnion mounts provide even more flexibility, as the cylinder can pivot freely. Spherical bearing mounts offer self-alignment, preventing side loads and extending cylinder life. These mounts are essential in mobile and heavy-duty applications that require the cylinder to adjust to changing angles or uneven surfaces.

Key Factors to Consider When Choosing a Hydraulic Cylinder Mount Type

AiSoar provides custom service for your hydraulic cylinder mount type , considering these factors if you have custom service.

Application Type: For stationary applications like presses, choose stable options such as foot mounts or flange mounts. For dynamic applications, like construction equipment, go with pivot mounts (e.g., clevis or trunnion) to allow flexibility and movement.

Load Direction: If the load is straight (axial), use foot or flange mounts for stability. If angular movement is required, pivot mounts (clevis, trunnion) prevent side loads and reduce wear.

Space Constraints: In tight spaces, flange mounts are ideal due to their compact attachment. Pivot mounts require more space, so they’re better suited for applications with room for movement.

Alignment Needs: For applications that demand precise alignment, choose foot or flange mounts. If self-alignment is necessary, spherical bearings are effective in accommodating misalignment.

Maintenance Requirements: If frequent maintenance is needed, tie-rod mounts allow for easy access. Flange mounts are also good for limited-access areas as they only require mounting at one end.

Installation Tips for Hydraulic Cylinder Mounting

Proper installation of hydraulic cylinder mounts is crucial for performance and longevity. Ensure alignment during installation to prevent side loads and binding. Tighten mounting bolts securely but avoid overtightening, as this can damage the mounts or misalign the cylinder. For pivot mounts, ensure that pivot points are properly aligned to avoid twisting or binding during operation. Following these installation best practices will help maintain the cylinder’s performance and minimize wear over time.

Summary

Choosing the most suitable mount type for your hydraulic cylinder involves considering factors such as the application type, load direction, available space, alignment needs, mounting location, and maintenance requirements. By selecting the right mount type, you ensure better performance, reduce wear, and extend the life of your hydraulic cylinder.

AiSoar Custom Hydraulic Cylinder Mount Type

Hangzhou Aisoar hydraulic technology Co.,Ltd

Tel: 86-571-87920309

Fax: 86-571-87926329

Mob&Wechat&Whatsapp: +86 13588456446

Email:Sales@ai-soar.com

www.aisoarhydraulics.com

ES

ES RU

RU