How to test a hydraulic cylinder

Step 1: Visual Inspection

Before any hands-on testing begins, perform a visual inspection of the hydraulic cylinder. Look for any signs of wear or damage on the cylinder body, piston rod, and seals. Any visible defects could indicate internal issues.

Step 2: Check for Leaks

Examine all connections and seals for hydraulic fluid leaks. Even a small leak can affect the performance of the cylinder and may lead to bigger problems if not addressed promptly.

Step 3: Measure the Operating Pressure

Using a pressure gauge, measure the operating pressure of the cylinder during operation. Compare this with the manufacturer's specified operating pressure to ensure it is functioning within safe limits.

Step 4: Test the Cylinder's Full Stroke

Activate the hydraulic cylinder throughout its full stroke in both directions. Look for any signs of hesitation, uneven movement, or 'stick-slip' behavior which could suggest internal issues or contamination.

Step 5: Assess the Piston Rod Deflection

With the rod fully extended, inspect for any bending or misalignment. Any deflection could lead to premature wear of seals or potential failure.

Step 6: Perform a Speed Test

Compare the extension and retraction speeds to the manufacturer’s specifications. Deviations in speed can indicate problems such as fluid viscosity issues, air in the system, or mechanical wear.

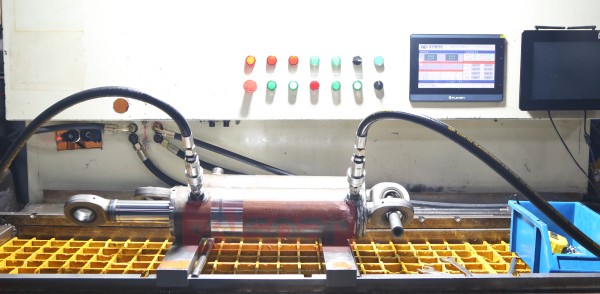

Step 7: Bench Test for Internal Leakage

For a more thorough examination, conduct a bench test where the cylinder can be safely pressurized while stationary, and check for internal leaks. This can be done by pressurizing the cylinder and monitoring for a drop in pressure, which would suggest an internal bypass of fluid.

Step 8: Test the End-of-Stroke Buffering

Ensure that the end-of-stroke cushioning (if present) functions correctly. It’s designed to slow down the piston at the end of its stroke to prevent impact damage.

Step 9: Analyze the Fluid Condition

Sample the hydraulic fluid for contamination, water, and air. Contaminated fluid can cause a myriad of problems and significantly shorten the life of a hydraulic cylinder.

Step 10: Conduct a Load Test

To verify that the cylinder can hold and operate under its maximum rated load, perform a static load test. Secure the cylinder in place, apply the maximum rated load, and hold for a specified period. Monitor the system for any performance changes or drops in pressure, which can indicate an inability to hold the load or potential structural issues.

Step 11: Document and Address

Keep a record of all testing results, and if any issues are found, take the appropriate measures to address them. This might include seal replacement, realignment, or professional hydraulic repair services.

AiSoar Hydrailic Cylinder

TEL: +86 18258822266

WhatsApp: +86 18258822266

ES

ES RU

RU