How to Repair Threaded Head Hydraulic Cylinders

If you're facing issues with a damaged threaded head hydraulic cylinder, you're not alone. Improper disassembly or lack of knowledge can lead to extensive damage, high repair costs, and long downtimes. The solution? Knowing how to properly disassemble and repair your hydraulic cylinders. This article will walk you through the process.

Repairing threaded head hydraulic cylinders requires careful disassembly to avoid damage. Follow our guide on cylinder disassembly, focusing on rod end locks, to restore your equipment efficiently.

Now that you have a quick overview, let’s explore the detailed steps of hydraulic cylinder disassembly.

Reasons for Disassembling a Hydraulic Cylinder

Hydraulic cylinders play a crucial role in various machinery, from construction equipment to agricultural machines. Over time, these cylinders may need to be disassembled for several reasons.

1.Worn-out seals

2.Damaged rods

3.Leaking fluid

4.Damaged cylinder housing

5.Inspect the internal components such as the piston, seal, and gland for wear and tear.

Disassembling the cylinder also helps to replace worn parts, clean the internals, and restore the cylinder's performance to its optimal condition. Without proper disassembly, you risk poor performance or even failure, which can lead to costly downtime in operations. If you notice any leaks, unusual noises, or a loss of power, disassembling the hydraulic cylinder could help you identify the problem.

Before dismantling we have to make sure, what type of cylinder we have:

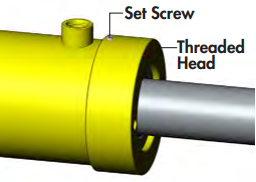

Repairing A Set Screw Style/Locking Ring Hydraulic Cylinder

Before starting the disassembly of a threaded head hydraulic cylinder, preparation is key to ensuring a smooth process.

1. Making sure to gather all necessary tools, such as wrenches, hydraulic cylinder pullers, and safety gloves. It’s important to inspect the cylinder for any obvious damage or leaks that might indicate the need for further repairs.

2. Ensuring that the hydraulic system is completely depressurized by turning off the machine and releasing any pressure from the hydraulic lines. If the cylinder has a lock on the rod end, you'll need to disengage that lock before proceeding.

3. Setting up your workspace to keep all tools and components organized. Proper preparation ensures a safer and more efficient disassembly process, reducing the chances of mistakes or injuries.

How to Disassemble a Threaded Head /Set Screw Cylinder

1. Remove the Set Screw: Begin disassembling threaded head cylinders by loosening the set screw and end cap, then remove the piston, rod, and gland assemblies.

2. Loosen the Gland: Use a conventional or C-spanner wrench to unscrew the gland. Loosen it carefully to avoid damaging the threads or other parts.

3. Pull Out the Rod Assembly: Gently pull the piston rod to remove the entire rod assembly, which includes the gland and piston, from the cylinder housing.

4. Detach the Piston: If necessary, remove the piston from the rod assembly by loosening the piston nut at the rod's end.

5. Remove the Gland Assembly: Slide the gland or end cap off the piston rod, taking care not to damage the components.

6. Replace the Seals: Inspect the seals in the gland assembly and replace any worn or damaged seals with new ones to ensure proper function.

7. Inspect the Components: Check the cylinder bore for any damage such as scoring, rust, or distortion. Examine the piston rod for signs of wear, bending, or other issues. If needed, you can hone the bore or replace the piston rod.

How to Re-assemble it:

Once new seals are in place, reinsert the rod through the gland assembly and end cap.

- Attach the piston back to the rod with the lock nut. Lubricate the seals and tube interior with hydraulic oil before installing the piston, gland, end cap, and rod.

- Securely hold the cylinder body in a vise and use a gentle rocking motion for component insertion.

- Apply anti-seize to the threads before installing the cylinder end-cap, then tighten the cylinder and set screw to the recommended torque levels.

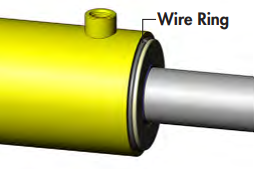

How to Disassemble a Wire Ring Cylinder

1. Remove the End Cap: Use a pipe wrench to remove the end cap, if present, which will expose the top of the gland.

2. Extend the Rod: Ensure the piston rod is fully extended from the cylinder housing to give you better access for disassembly.

3. Remove the Wire Ring: Rotate the gland within the bore to eject the wire ring through the hole in the side of the cylinder head. The angle of the hole will indicate the direction the gland needs to turn to release the ring.

4. Extract the Rod Assembly: Once the wire ring is fully ejected, pull out the piston rod along with the piston and gland assembly.

5. Check for O-Rings: Inspect the bore area where the gland was located for any O-rings. If present, remove and set them aside for replacement.

6. Disassemble the Rod Assembly: As with the threaded head cylinder, remove the piston from the rod and replace any damaged seals or components.

7. Remove the Plastic Ring: Don’t forget to remove the plastic ring from the internal groove on the piston rod if it’s present.

8. Reassemble the Cylinder: To reassemble, follow the disassembly steps in reverse order, ensuring all parts are clean, lubricated with fresh hydraulic oil, and properly reinstalled.

Three things to inspect during disassembly

It's crucial to thoroughly examine the rod for bends or scratches. A bent rod should be straightened or replaced, while scratches might indicate the need for a new tube if the piston seal is damaged or missing.

Inspect the rod seal for any distortion, which often points to a bent rod or a worn guide bushing. If the tube's interior is scratched, scored, or pitted, it requires honing, or replacement if the damage is severe.

Leaks not caused by visible issues with the shaft or cylinder might indicate damaged seals. Remember, surface scratches and gouges where the seal is fitted can also cause leaks. Handle seals with care during installation.

Repairing the hydraulic cylinder for its life is extremely important, so when the cylinder's use time is too long, inspect it immediately.

If you have any complex or technical inquiries regarding hydraulic cylinders, AiSoar's team of experts is ready to provide detailed answers. From nuanced aspects of design and operation to specialized maintenance and troubleshooting techniques, they're equipped to address advanced queries with precision and expertise.

ES

ES RU

RU