How to make a hydraulic cylinder?

Hydraulic cylinders take on a lot of work and power. But it also takes a lot of work and power to make a complete hydraulic cylinder.

First and foremost, hydraulic cylinder manufacturers use very sharp drills to work through steel and create the piston of a hydraulic cylinder. Workers place different sealing devices to ensure that fluids do not leak away from the piston and that debris or dirt stays clear of the piston rod.

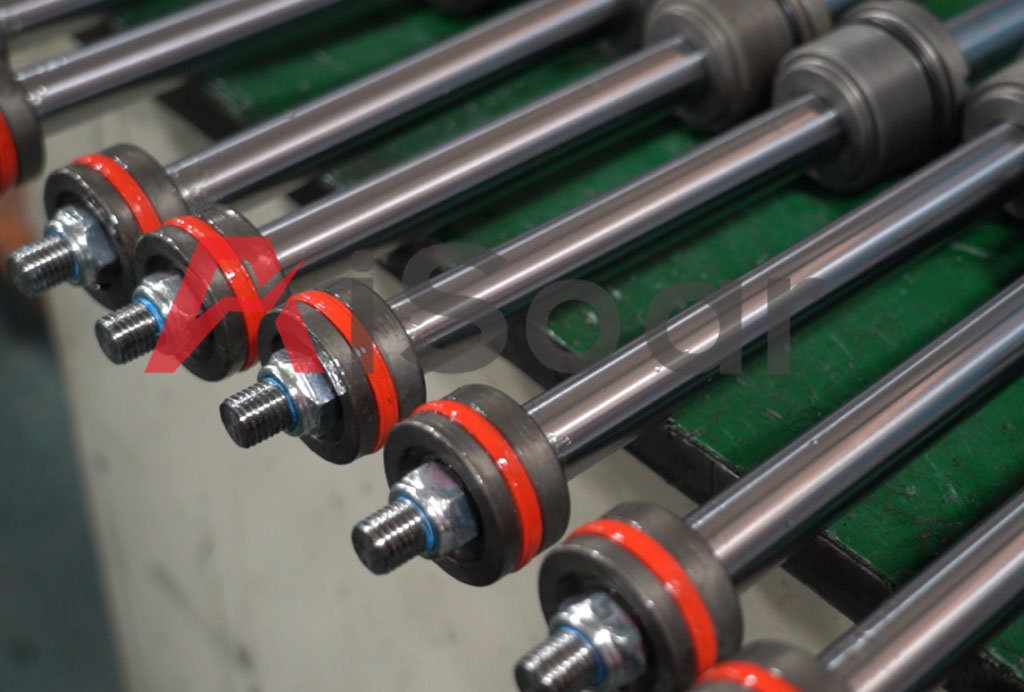

Much of the hydraulic cylinder creation process is actually done by hand. Machines do some part of the process, but such sealers are usually put on carefully by human workers. Their care and attention to detail allow the piston to remain undamaged. Any sort of damage to the piston can ruin the effectiveness of a hydraulic cylinder, so workers take great care down to the final screw.

The Parts of a hydraulic cylinder

Understanding the various pieces that make up a hydraulic cylinder can help us to understand the construction.

The hydraulic cylinder is basically composed of the following parts:cylinder barrel, piston, piston rod, gland ,cap,seals.

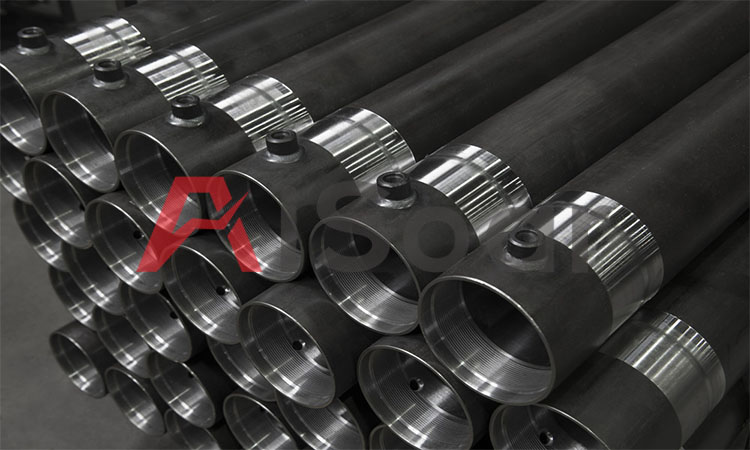

Cylinder barrel

Piston & Piston Rod

Gland & Cap

Seals

The process of making a hydraulic cylinder

1.Design 2.Machining 3.Washing 4.Assembling 5.Inspection and testing 6. Painting 7.Packing

Design

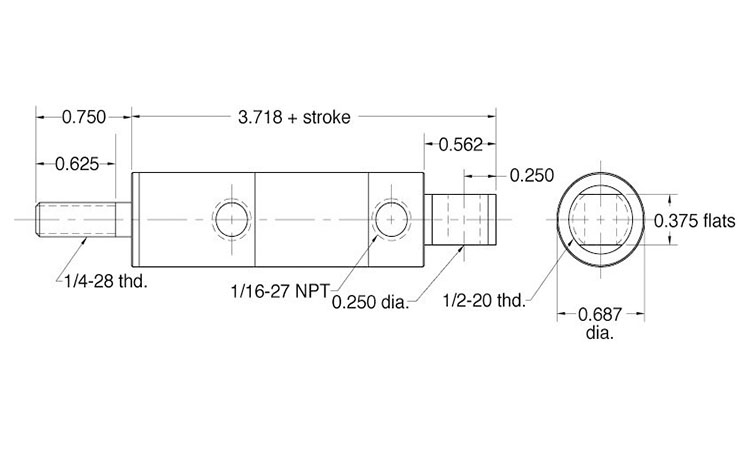

The cylinder is first designed by a team of hydraulic cylinder engineers, taking into account the use of the hydraulic cylinder and the environment that it will be in. This dictates materials, coatings, seals and other specialist parts. Hydraulic systems are designed in compliance with any external legislation that relates to the industry that it is being designed for.

Machining

Once the design has been finalised, the machine shop engineers start producing the cylinder. Cylinder rods and other parts are bored to minutely accurate measurements using highly specialised machinery.

Washing

Before assemble all the part of the hydarulic cylinder,wahsing all the parts is a necessary step,which can ensure the accuracy of oil cylinder installation and prolong its service life.

Assembling

The assembly department puts all the components together (rod, pistons, tubes and seals). The assembly department assembles the cylinder, ready for inspection and testing.

Inspection and testing

The inspection department offers rigorous testing of all hydraulic cylinders before they are approved for the client. They perform pressure, pull and load tests as required.

Painting

Paint on the hydraulic cylinder can make it have excellent corrosion resistance,excellent resistance to abrasion, acids & solvents,exceptional gloss and color retention.

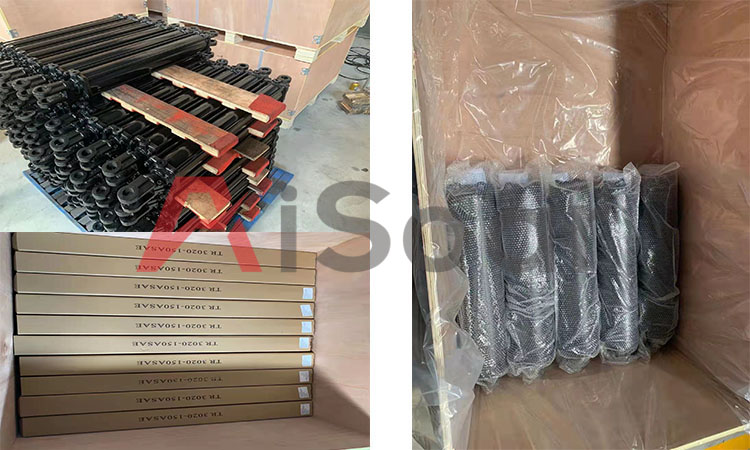

Packing

Understanding the parts, and creation of a hydraulic cylinder can help lead you to a better understanding of hydraulics in general.

If you have any question about hydraulic cylinder,please feel free contact us.

Hangzhou Aisoar hydraulic technology Co.,Ltd

Tel: 86-571-87920309

Fax: 86-571-87926329

Mob&Wechat&Whatsapp: +86 13588456446

Email:Jack@ai-soar.com

ES

ES RU

RU