HOW TO CALCULATE CYLINDER FORCE OUTPUT

Hydraulic cylinders are used in many industries, such as agricultural machinery, hydraulic presses, cranes, garbage trucks, etc.

The hydraulic system has many important components, all of which work together to work properly. The force that the hydraulic cylinder will exert must be calculated correctly. Make sure you not only have the correct cylinder for your system, but also the correct cylinder for your project needs and specifications.

The hydraulic cylinder is a key part of the hydraulic system and the backbone of the machine's operation. Anything that is pushed, pulled, lifted, or dropped is due to the work of hydraulic cylinders in trucks, cranes, bulldozers, and tractors. Without the design and production of hydraulic cylinders, the industrialized world as we know it would not exist. Although these machines perform complex tasks, their design is very simple.

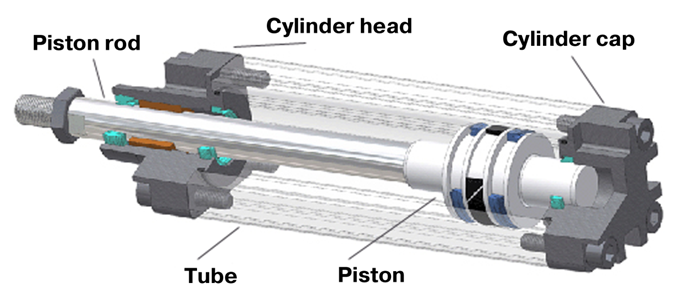

The cylinder is composed of five main components: piston, piston rod, tube, cylinder head and cylinder cap.

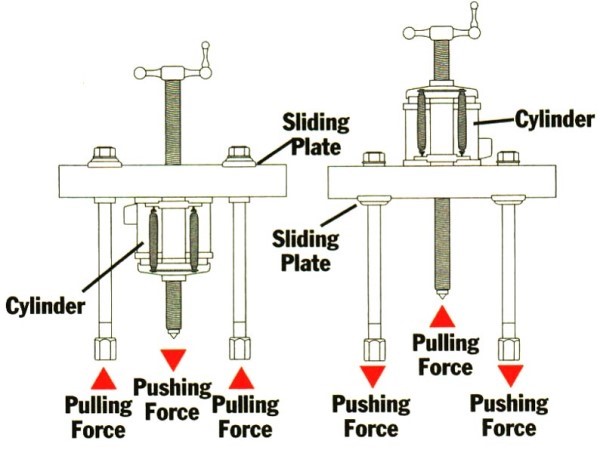

CYLINDER PUSH FORCE VS PULL FORCE

When looking for a hydraulic cylinder, you need to consider whether you are looking for pressure or pull capacity. This is also a key factor when calculating the overall hydraulic cylinder force output. If you need a cylinder that can be extended and retracted with hydraulic power, in other words, has the ability to push and pull, then a double-acting cylinder is what you are looking for. It is generally accepted that double-acting cylinders are a stronger option, capable of using less energy to accomplish the same work as single-acting cylinders.

If the hydraulic cylinder you are using only pushes objects in motion, then you are using a single-acting cylinder. The piston in a single-acting cylinder allows fluid to pass through hydraulic components in a one-way track. Inside, you will find a steel spring that helps retract the piston.

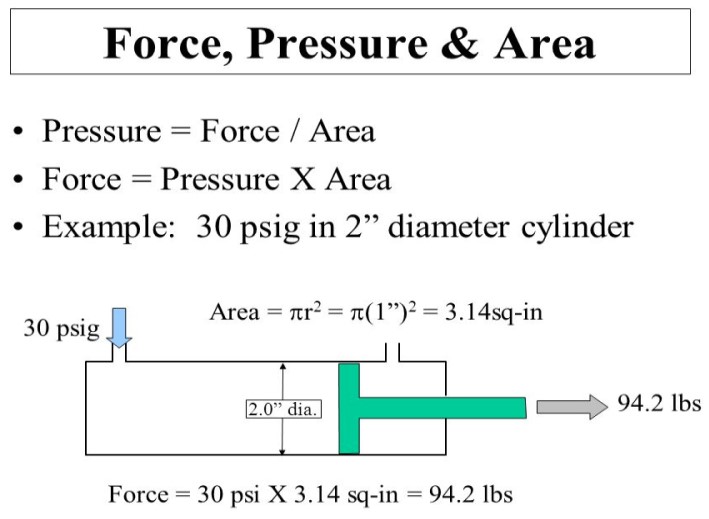

CALCULATING THE FORCE OUTPUT

In order to correctly calculate the applied pressure extruded from the hydraulic cylinder, it is important to understand all the working parts. Each part will affect the expansion calculation and will affect the result of the evaluation formula. To calculate the total force correctly, you can multiply the total square inch surface area of the piston by the pressure difference across the piston. The same single-acting formula can be applied to both types of hydraulic cylinders because you only need to measure the driving force that occurs in either hydraulic cylinder.

CYLINDER PUSH FORCE FORMULA

When working with hydraulic cylinders that push and pull the object at hand, the formula is slightly modified. The main factor causing the slight change in the calculation is the loss of surface area. For example, compared to the single acting side, there is the entire area of the piston. On the retracted side of the cylinder, you can now take the piston rod area away from the entire surface. Therefore, the calculation takes into account the surface area of the entire rod area. To do so follow the formula below:

Area = D^2 (diameter) x π/4

Now that you have formulated the working area of the system’s cylinder you can plug that data into the formula below and calculate the push force of your hydraulic cylinder.

Push force = PSI (system pressure) x D^2 (diameter) π/4

(Push force = PSI x Area)

If you have any further questions about hydraulic cylinders, please contact email: alice@ai-soar.com or contact us.

|

AISOAR HYDRAULIC CYLINDERS |

ES

ES RU

RU