How do you calculate hydraulic cylinder?

Hydraulic cylinder can be seen everywhere in our life, do you know how to calculate hydraulic cylinder?

In order to correctly determine the size of the hydraulic cylinder on the mold, please follow the steps below.

1. Train the mold designer to understand the potential maximum plastic pressure so that he/she can accurately calculate the plastic pressure of the cavity surface area on the part. When peak plastic pressure must be considered, many people only consider holding/holding pressure. Also, don’t just be based on the materials used, as some factors can greatly affect the pressure. If you are not sure, round it up. Note that if you want a powerful tool and process, then never round it. Once the maximum plastic pressure is determined, the rest is simple.

2. Accurately calculate the cavity surface on the surface area of the component. Then multiply that number by the maximum plastic pressure we discussed. The result will be the pressure required to design the cylinder.

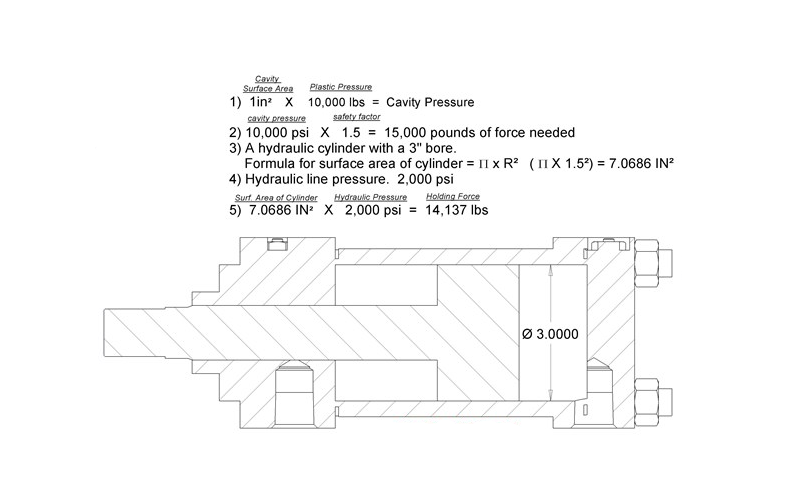

3. Determine the bore of the cylinder. Usually, I design the hole size so that it exceeds the cavity pressure by 1.5 times to ensure robustness. For example, if the expected cavity pressure is 10,000 psi and the cavity surface area of the component is 1 square inch, we know that there will be 10,000 pounds of force acting on the component (10,000 pounds per square inch X 1 square inch). If we multiply the ratio of 10,000 by 1.5, we will find that we need about 15,000 pounds of force to offset the cavity pressure.

Give it a try. Let us determine the required hydraulic cylinder hole size by calculating the surface area of the cylinder hole size and the hydraulic pressure used on the machine or hydraulic pump truck. For example, for a hydraulic pressure of 2,000 psi, calculate the surface area of the aperture, which is 3.14 X R2. If you use a 3 inch inner diameter cylinder, calculate the radius (1.5 x 1.5 x 3.14), which is equal to 7.065 square inches of surface area. Then multiply this number by the 2,000 hydraulic psi used. This is equivalent to a holding force of 14,130 psi (7.065 square inches X 2000 hyd psi). In this case, a 3-inch caliber cylinder should provide a strong condition.

If you have any further questions about hydraulic cylinders, please contact email: alice@ai-soar.com or contact us.

|

AISOAR HYDRAULIC CYLINDERS |

ES

ES RU

RU