Dump Trailer Hydraulic Cylinder: Types, Functions, Maintenance & Troubleshooting Guide

Dump trailer hydraulic cylinders are essential for efficient operation, but choosing the wrong one or neglecting maintenance can lead to costly repairs and downtime. This impacts productivity and increases operational costs. The solution lies in selecting the right hydraulic cylinder and maintaining it regularly to ensure smooth performance.

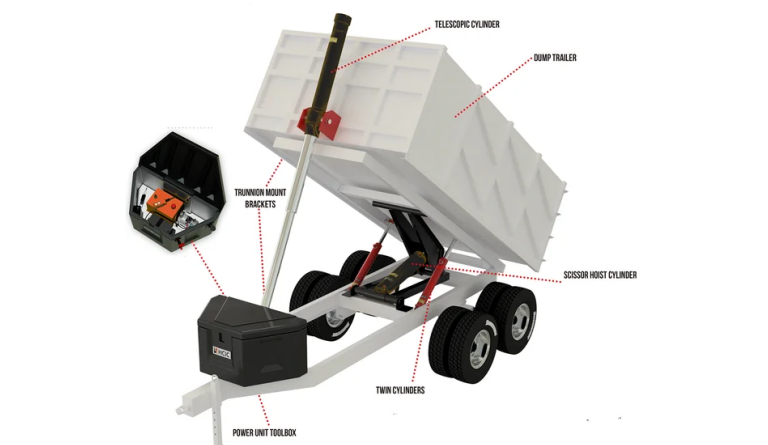

Dump trailer hydraulic cylinders are integral to lifting mechanisms, powering heavy-duty construction and mining vehicles. These cylinders enable efficient lifting and unloading through hydraulic force, ensuring smooth operations in tough environments.

Main Types of Hydraulic Cylinders in Dump Trailer

There are several types of hydraulic cylinders used in dump trucks, each suited to different lifting needs:

Scissor Hoist Hydraulic Cylinder For Dump Trailer

A scissor hoist hydraulic cylinder for trailers is a crucial component that enables efficient and reliable lifting and unloading. Typically used in dump trailers, these hydraulic cylinders utilize a scissor mechanism to provide enhanced strength and stability.

Telescopic Hydraulic Cylinder For Dump Trailer

A telescopic hydraulic cylinder for dump trailers is a specialized hydraulic component designed to provide powerful lifting capacity in a compact form. These cylinders are particularly useful in applications where a long stroke is required, but space is limited. They consist of multiple nested tubes (or stages), which extend progressively when hydraulic fluid is pumped into the cylinder. This design allows the cylinder to achieve a long extension without the need for a long, bulky unit.

Outrigger cylinder For Dump Trailer

An outrigger cylinder for a dump trailer is a hydraulic component used to stabilize and support the trailer during unloading. Outriggers are critical for maintaining the trailer's stability when lifting the bed, especially when carrying heavy or uneven loads. The outrigger hydraulic cylinder extends and retracts to stabilize the trailer’s frame, preventing it from tipping or shifting during the unloading process.

How It Works:

When the dump trailer is loaded, hydraulic fluid is pumped into the outrigger cylinder, causing it to extend and lift the trailer’s frame. This action stabilizes the trailer by spreading its weight over a larger area, ensuring that the trailer remains steady during the unloading of heavy materials like gravel, sand, or construction debris.

Once the unloading process is complete, the hydraulic pressure is released, and the outrigger cylinder retracts back into its original position, allowing the trailer to return to its normal operating state. This quick extension and retraction process helps ensure safety and operational efficiency.

Telescopic Hydraulic Cylinder VS Scissor Hoist Hydraulic Cylinder

The telescopic hydraulic cylinder and the scissor hoist hydraulic cylinder are both crucial components in heavy-duty lifting applications, but they operate on different principles and are suited for different types of tasks. Here's a comparison of the two:

| Feature | Telescopic Hydraulic Cylinder | Scissor Hoist Hydraulic Cylinder |

| Operating Mechanism | Nested tubes, progressive extension | Scissor arms, interlocking hydraulic cylinders |

| Lifting Capacity | High lifting power, compact design | Lifting power with stability |

| Stability | Moderate, less stable with uneven loads | Excellent stability, even with uneven loads |

| Applications | Dump trucks, cranes, material handling | Dump trailers, garbage trucks, elevating platforms |

| Space Efficiency | Very compact when retracted | Compact but limited lifting height |

| Cost and Maintenance | More expensive, complex maintenance | More affordable, easy to maintain |

| Advantages | Long reach, high lifting power | Stable lifting, ideal for shifting loads |

Maintenance and Troubleshooting Guide

Dump Trailer Hydraulic System: Maintenance and Troubleshooting Guide

1. Routine Maintenance

Regular maintenance is crucial to ensure the smooth operation and longevity of the hydraulic system in dump trailers. Here's a breakdown of tasks:

1.1 Hydraulic Fluid Maintenance

| Check Fluid Levels | Hydraulic fluid should be at the recommended level. Low fluid can lead to overheating, erratic movement, and poor lifting performance. |

| Fluid Replacement | Replace the hydraulic fluid at least once every 1-2 years, or as recommended by the manufacturer. Contaminated or old fluid can reduce system efficiency. |

| Fluid Quality | Use the recommended type of hydraulic fluid (e.g., mineral oil-based or synthetic). Always ensure the fluid is clean and free from debris. |

| Fluid Temperature | Overheating can damage seals, hoses, and other components. Check the fluid temperature regularly to avoid overheating. |

1.2 Check and Replace Hydraulic Hoses

| Visual Inspections | Check for cracks, wear, or leaks. Replace hoses if damaged. |

| Pressure Test | Inspect hoses under pressure to ensure they are functioning properly and aren’t leaking under load. |

| Hose Routing | Ensure hoses are not rubbing against other parts or exposed to excessive heat, which could cause premature wear. |

1.3 Inspect Cylinder Seals and Rods

| Inspect Seals | Check for leaks around the cylinder seals. If you notice leakage, the seals should be replaced immediately to avoid fluid loss. |

| Clean Rods | The rod should be kept clean and free of debris. Dirt or particles on the rod can damage seals and cause hydraulic fluid to leak. |

| Inspect for Rust or Corrosion | Ensure the cylinder rods are free from rust. If rust is present, it should be cleaned, and if severe, the rod may need replacement. |

1.4 Check Hydraulic Pump and Valve

Inspect Pump Operation: Ensure the hydraulic pump is delivering adequate pressure. If the pump is weak, it may need servicing or replacement.

Valve Function: Ensure all valves are functioning properly and responding to input commands. Faulty valves can cause erratic movement or failure to lift.

1.5 Lubrication

Lubricate Moving Parts: Apply grease or lubricants to any moving parts, such as pins, joints, or linkage points, to ensure smooth operation. Use the recommended type of lubricant.

Check for Wear: If any parts exhibit wear or increased resistance, consider lubrication or part replacement.

Suggestions for Purchase and Replacement

When purchasing or replacing a hydraulic cylinder for a dump trailer, it’s essential to consider factors like load capacity, stroke length, and the operating environment. For heavy-duty applications, such as mining or construction, choosing a telescopic hydraulic cylinder or a double-acting cylinder is often the best choice. Ensure that the hydraulic cylinder is compatible with the truck’s lifting mechanism and meets the required technical specifications. It’s also important to choose a reliable manufacturer and ensure the cylinder is built for long-term durability under tough conditions.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Email: sales@ai-soar.com

Website: www.aisoarhydraulics.com

ES

ES RU

RU