A Guide to Hydraulic Cylinder Installation

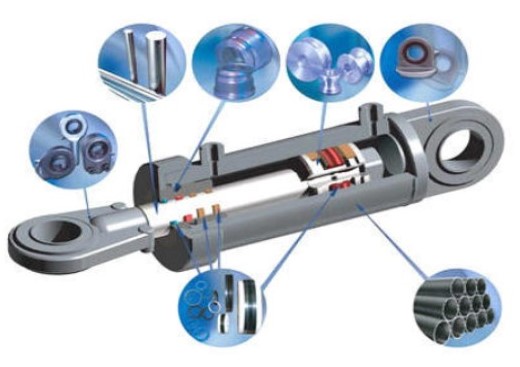

A hydraulic cylinder has five basic parts. These are the piston rod, rod-end port, barrel, piston, and cap-end port.

Hydraulic cylinders can be seen everywhere in our lives, do you know how to install a new hydraulic cylinder?

Before installing a new hydraulic cylinder, the first step is to create a safe working space for disassembly and installation. Make sure the area is clean and dry to keep the cylinder components free from contamination during installation. After setting up the workspace, you can proceed with the other preparation steps below.

1. Before connecting all components to the new hydraulic system, lubricate all components and flush hydraulic pipes

2. Make sure that no pressure or external force is added to the hydraulic system when reducing the load.

3. Before starting any maintenance, close the shut-off valve, turn off the hydraulic pump and release the circuit pressure.

SAFETY PRECAUTIONS FOR HYDRAULIC CYLINDER REPLACEMENT

Before starting any hydraulic cylinder work, prepare appropriate protective equipment. The equipment should include safety goggles/glasses, boots, gloves, ear protection and safety helmets.

Other safety precautions include:

- Keep hands and feet away from the cylinder during testing.

- Choose a suitable bracket to support and support the hydraulic cylinder.

- Make sure that the cylinder is not running and cannot be started during the disassembly and installation process. Depending on your working environment, you may need additional barriers to prevent movement.

As a general rule, you should not exceed the device rating, and you should not set the safety valve at a pressure higher than the maximum rated pressure.

Install Your New Hydraulic Cylinder

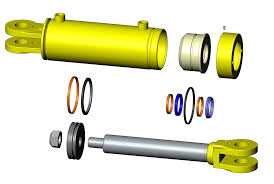

Before installing a new hydraulic cylinder, first check the hydraulic cylinder seals, end dampers and accessories to make sure you have the correct type and size. Next, check all bearings and pins to make sure they are properly lubricated. You should also check the hydraulic cylinder connection, including the correct size and position.

- Adjust the installation size of the hydraulic cylinder to the pre-check value. Lock the holes fixed on the piston rod. If you are unsure of the measured value, please compare the measured value with the installation measured value mentioned in the equipment hydraulic cylinder assembly drawing.

- Adjust the new cylinder end damping and copy them to reflect the old hydraulic cylinder.

- Make sure that the directions of the hydraulic cylinder connection holes are aligned correctly.

- Lift the hydraulic cylinder and secure it in place.

- Tighten the fasteners of the hydraulic cylinder.

- Remove the protective plug.

- Tighten hydraulic hoses or pipes.

- Remove the lifting equipment and/or remove the support from the hydraulic cylinder.

Final Steps for Installing Your New Hydraulic Cylinder

- Fix the removed guards in place. Connect system energy

- If a test connector is included/available, bleed the hydraulic cylinder. Run the cylinder until there is no air in the system and the movement is smooth.

- Adjust the end pads of the new hydraulic cylinder so that there is no impact at the end of the stroke.

- After the test duty cycle, make sure that the adjustment stays in place/stays in place.

If you have any further questions about hydraulic cylinders, please contact email: alice@ai-soar.com or contact us.

|

AISOAR HYDRAULIC CYLINDERS |

ES

ES RU

RU