How to Choose a Custom Hydraulic Cylinder

The process of choosing the right hydraulic cylinder for your specific application may seem routine or even repetitive at times, but it's important to maintain a fresh outlook in beginning this process and to always remember to consider several basic components.Ultimately, multiple factors will determine what components will need customization and what components are acceptable as standard issue. Industry guidelines and standards can play a role in component customization and hydraulic design. Additional design considerations include:

- Cylinder body type material. Hydraulic cylinders can be manufactured with a steel- or chrome-plated body. Depending on your application, custom hydraulic cylinders can be made with alloy steels such as stainless steel or brass.

- Cylinder bore size. The force required determines bore size as it is relative to operating pressure.

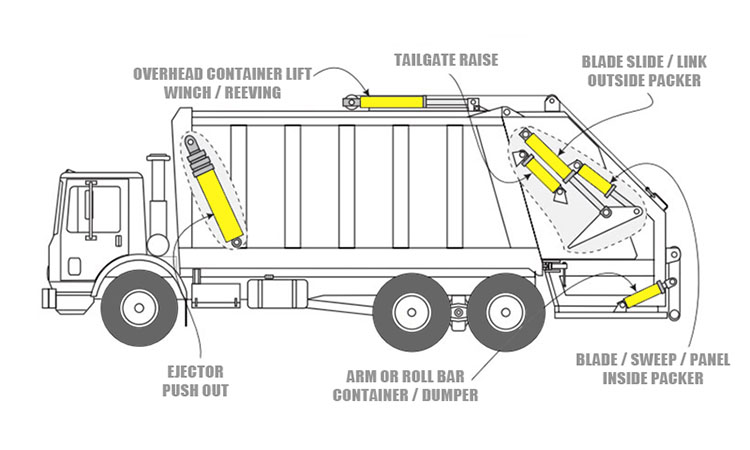

- Cylinder configurations. Configurations depend on your application needs. Custom hydraulic engineers should work with you to determine the best configuration to meet your application and performance requirements.

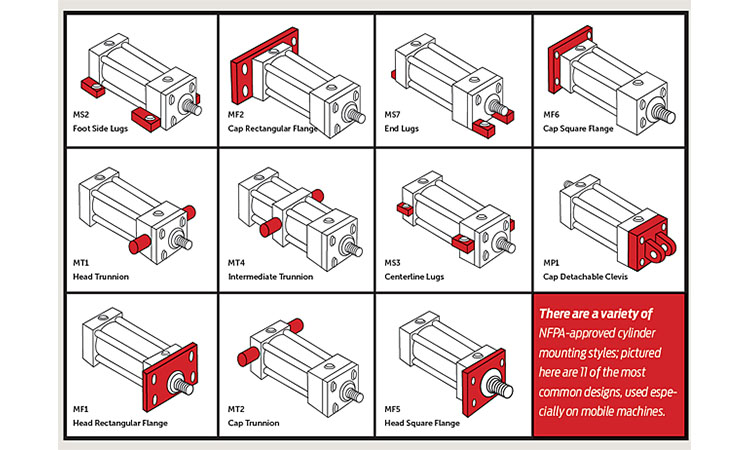

- Mounting styles. The three types of mounting styles for hydraulic cylinders include:

- Fixed mounts. Absorb forces and can include medium-duty and heavy-duty mounts.

- Pivot mounts. Similar to fixed mounts, pivot mounts absorb forces and can include medium-duty and heavy-duty mounts.

- Off-set pivot mounts. Mounts below the centerline and supports the entire cylinder.

- Piston rod size. Custom piston rod sizes can be manufactured in various alloys, depending on the needed column strength.

- Rod ends/threading. Can be made in inch or metric, diameter availability in 4-rod end styles.

- Can be customized based upon application needs and temperature/fluid requirements.

- Average hydraulic cylinders can accommodate speeds up to 3.28 feet per second.

- Stroking distance. Can be customized depending on the application. Pressure rating and rod diameter must be considered when making customizations.

- Stop tubing. Can increase the distance between the rod and piston bearings. Stop tubing can improve stability and enhance piston bearing shelf life.

1.Consider the Size

The first key piece of information to consider when choosing a bore size is the operating pressure. The basic operating pressures that are commonly used range from: 500 psi to 3000 psi. These pressures match up with NFPA medium and high pressure cylinders. Knowing the operating pressure you would like to use will help drive the selection of the cylinder bore size.

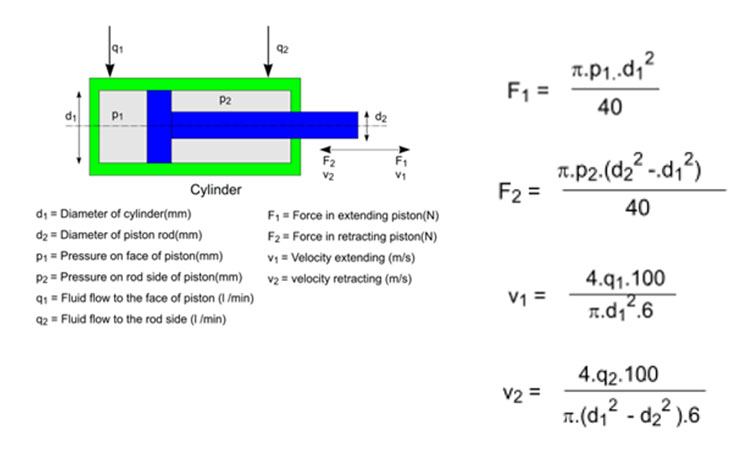

The second key piece of information needed to select the bore size is the amount of force required for the application. A quick formula for finding the approximate bore size for the extend direction of the cylinder is as follows:

F = force required (lbs.)

P = operating pressure (psi.)

D = bore diameter (in.)

D = F / (.7854 * P)

Typically the resulting bore diameter is rounded up to the next common standard bore size.

2.Conisder the mount

Cylinder mounts can be divided into two basic categories: pivoted and straight line. Selecting the right mount for an application mainly depends on the desired movement of the load. Pivoted mounts can be used where a load needs to move through an arc and include mounts such as Trunnion and clevis.

In comparison to pivoted mounts, straight line mounts are used when the load only needs to move in a linear direction and include mounts such as front head flange and side lug. It is necessary to consider the desired movement of the load specific to your application to ultimately determine the type of mount.

3.Environmental Conditions

Knowing where the cylinder is going to operate is important for selecting the appropriate materials, seals, and finishes. The material of the cylinder can be modified to meet specific environmental conditions. A common example, is selecting stainless steel components for corrosion resistance on wash down food production equipment. The cylinder seals can be changed for a variety of reasons, including high or low temperatures or special operating fluids, such as water glycol or phosphate ester fluids. Cylinder finishes can include special metal plating or paint finishes to meet a variety of indoor and outdoor applications.

Another way to determine the right sized hydraulic cylinder for your lift is to view or download our catalog. You can also call us and one of our knowledgeable representatives will help you find the right hydraulic cylinder for your application.Aisoar has the expertise to help you with your requirements and the high quality hydraulic cylinders, hydraulic pumps and hydraulic systems to get the job done.

Hangzhou Aisoar hydraulic technology Co.,Ltd

Tel: 86-571-87920309

Fax: 86-571-87926329

Mob&Wechat&Whatsapp: +86 13588456446

Email:Jack@ai-soar.com

ES

ES RU

RU